|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

rickofudall

Joined: 19 Sep 2009

Posts: 1392

Location: Udall, KS, USA

|

Posted: Tue Nov 25, 2014 5:50 pm Post subject: alternator / generator Posted: Tue Nov 25, 2014 5:50 pm Post subject: alternator / generator |

|

|

Ken, I don't know how far along you are in crafting your airplane's electrical architecture, but may I suggest you use Bob's Figure Z-16 that is designed for the 912/914. It is a more capable architecture than the Z-17 that I have used twice with Rotax 582 powered airplanes and with which I have been very satisfied. it is crafted to accomplish what you are asking about by using a contactor  to control the alternator. In addition, by using an S700-2-10 On-On-On switch you get the effect of a master switch and have a battery only mode for system testing (or to run on but locking out the starter) and a run mode that actuates the starter. I also appreciate that it does away with a bulky key switch to control the mags and starter by using a push button for the starter and SPST toggle switches to control the "mags". This is particularly handy when you wish to crank the engine over with the ignition off and top plugs out to charge the oil system before first engine start (Rotax ignition modules do not tolerate being fired while the plugs are not grounded. All the current is forced through one little diode that promptly burns up, cannot be replaced, and the cost of two new ignition modules is about $2500 plus installation. Not a mistake you want to make). Well, those are just a few of my reasons for recommending the Z-16. There are others on here who have used it and can chime in.

Rick

On Tue, Nov 25, 2014 at 12:20 AM, Ken Ryan <keninalaska(at)gmail.com (keninalaska(at)gmail.com)> wrote:

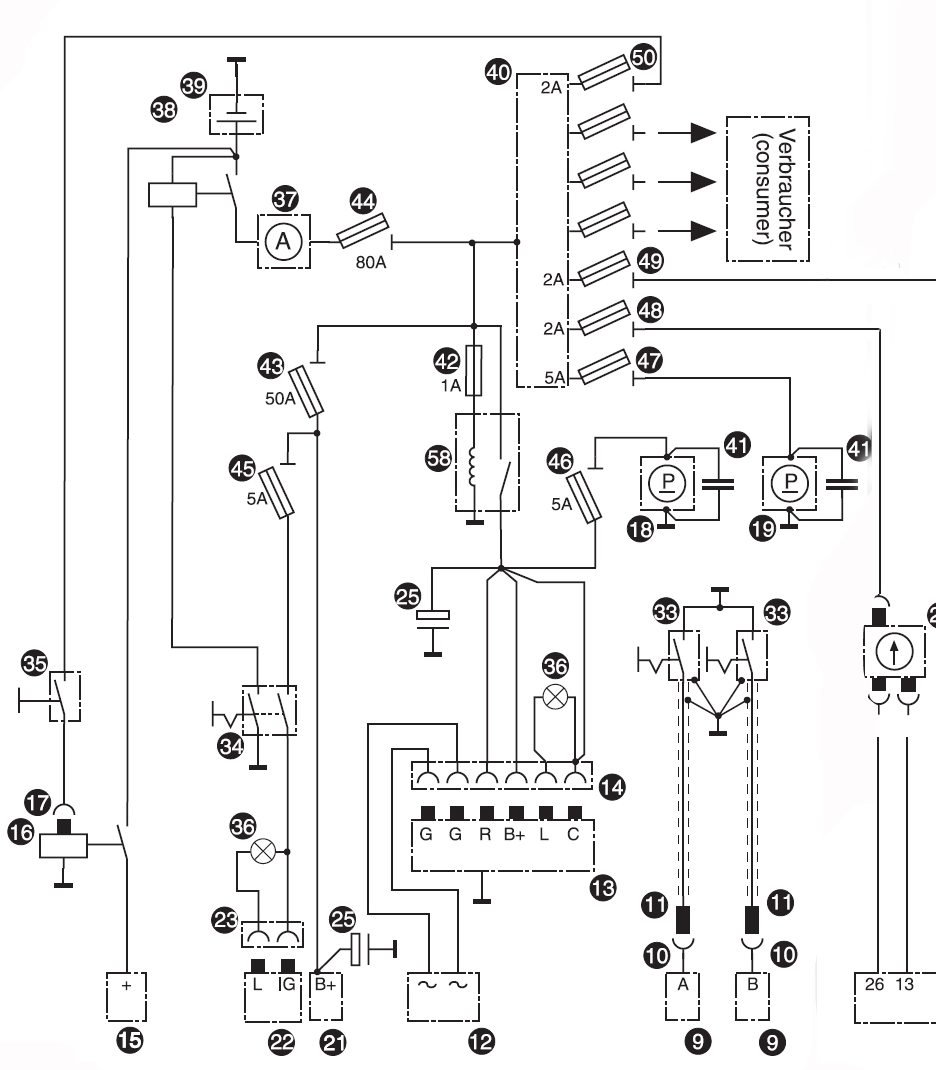

| Quote: | Rick, It's the wiring diagram from the Installation Manual for the 914.

On Mon, Nov 24, 2014 at 7:08 PM, Richard Girard <aslsa.rng(at)gmail.com (aslsa.rng(at)gmail.com)> wrote:

| Quote: | Ken, I've been off the forum for a few weeks and just saw your request for info on the Rotax alternator (dynamo). Can you quote chapter and verse of the manual you are referencing? One of my custormers has a 912 in a JA Highlander that was down for months fixing a long list of defects found during the annual conditional inspection and the battery started the engine just fine when we were done. The 582 on my Kolb has the same basic alternator. I did a major rebuild on the airplane and it was down for over 18 months. The engine started right up when I took it out and that was with a five year old 18 AH  SLA battery.

Rick Girard

On Wed, Nov 12, 2014 at 12:47 PM, Ken Ryan <keninalaska(at)gmail.com (keninalaska(at)gmail.com)> wrote:

| Quote: | Thanks Bob,

I was wondering about that 80 amp fuse. It seems better to connect the bus directly to the battery. With regards to the 1 amp fuse that you say is unnecessary, why do you say that? Isn't it there to protect the wire that runs from the battery to relay 58? I think the reasoning behind wiring one fuel pump to the generator, is because the 914 relies on an electric fuel pump, and they are trying to provide two independent power sources for each pump.

On Wed, Nov 12, 2014 at 9:18 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 11:01 2014-11-12, you wrote:

| Quote: | | Thanks Bob. I do have the book. I am building a Just Aircraft SuperSTOL. A previous lister said that the IG wire from the external alternator needs to be disconnected to avoid drawing down the battery, which it is on the Rotax diagram (via the master switch). Are you saying that you disagree with this and that the IG wired does not need to be disconnected to avoid drawing down the battery? |

Ooops . . . sorry 'bout that. We're talking about the wound-field

alternator . . . not the PM machine. That light doesn't work with much more

intelligence than that annunciator on the PM rectifier/regulator.

It's definitely dark when the alternator is working but may

not light when the alternator is inadequate to system

needs. I don't use those outputs either.

If you're planning on ACTIVE NOTIFICATION OF LOW VOLTS then

you can simply leave the light off the panel and leave the

terminal disconnected.

But you're correct, when wired per the Rotax drawing, IG gets

disconnected when the big-alternator switch is OFF . . . so if

you plan to use the light, wired as shown eliminates the

concern.

An interesting feature of their wiring gives you no control

over the little alternator . . . it is automatically switched

ON via relay (5 with an unnecessary, 1A fuse in the coil with an unnecessary, 1A fuse in the coil

lead. This relay closes as soon as you turn on the master

switch and will stay closed as long as the engine is running

even if battery relay (3 is opened. Bringing engine is opened. Bringing engine

rpm down will slowly drop voltage on the bus . . . and

might cause the little-alternator relay to drop but

this raises all kinds of questions about the behaviors

of the ship's accessories.

The relay will certainly drop after the engine is shut

down.

Another interesting feature uses the little-alternator

output to power up one of two fuel pumps whether or not

the master switch is ON.

The 80A breaker is, in US TC aircraft philosophy, not

necessary or useful.

[img]cid:.0[/img]Â Â Â Â Â Â Â Â

Bob . . .

|

|

--

Believe those who are seeking the truth, doubt those who find it.

-Andre Gide

|

|

--

Believe those who are seeking the truth, doubt those who find it.

-Andre Gide

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

274.22 KB |

| Viewed: |

11492 Time(s) |

|

_________________

The smallest miracle right in front of you is enough to make you happy.... |

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 429

|

Posted: Wed Nov 26, 2014 1:14 pm Post subject: alternator / generator Posted: Wed Nov 26, 2014 1:14 pm Post subject: alternator / generator |

|

|

Rick,

I will be incorporating Robert Paisley's Bus Manager, along with two lithium batteries, and am trying to figure out how the Rotax wiring diagram relates to that. Info on Bus Manager can be found here if interested:Â http://flyefii.com/bus_manager/Bus_Manager_Installation_Instructions.pdf

On Tue, Nov 25, 2014 at 5:49 PM, Richard Girard <aslsa.rng(at)gmail.com (aslsa.rng(at)gmail.com)> wrote:

| Quote: | Ken, I don't know how far along you are in crafting your airplane's electrical architecture, but may I suggest you use Bob's Figure Z-16 that is designed for the 912/914. It is a more capable architecture than the Z-17 that I have used twice with Rotax 582 powered airplanes and with which I have been very satisfied. it is crafted to accomplish what you are asking about by using a contactor  to control the alternator. In addition, by using an S700-2-10 On-On-On switch you get the effect of a master switch and have a battery only mode for system testing (or to run on but locking out the starter) and a run mode that actuates the starter. I also appreciate that it does away with a bulky key switch to control the mags and starter by using a push button for the starter and SPST toggle switches to control the "mags". This is particularly handy when you wish to crank the engine over with the ignition off and top plugs out to charge the oil system before first engine start (Rotax ignition modules do not tolerate being fired while the plugs are not grounded. All the current is forced through one little diode that promptly burns up, cannot be replaced, and the cost of two new ignition modules is about $2500 plus installation. Not a mistake you want to make). Well, those are just a few of my reasons for recommending the Z-16. There are others on here who have used it and can chime in.

Rick

On Tue, Nov 25, 2014 at 12:20 AM, Ken Ryan <keninalaska(at)gmail.com (keninalaska(at)gmail.com)> wrote:

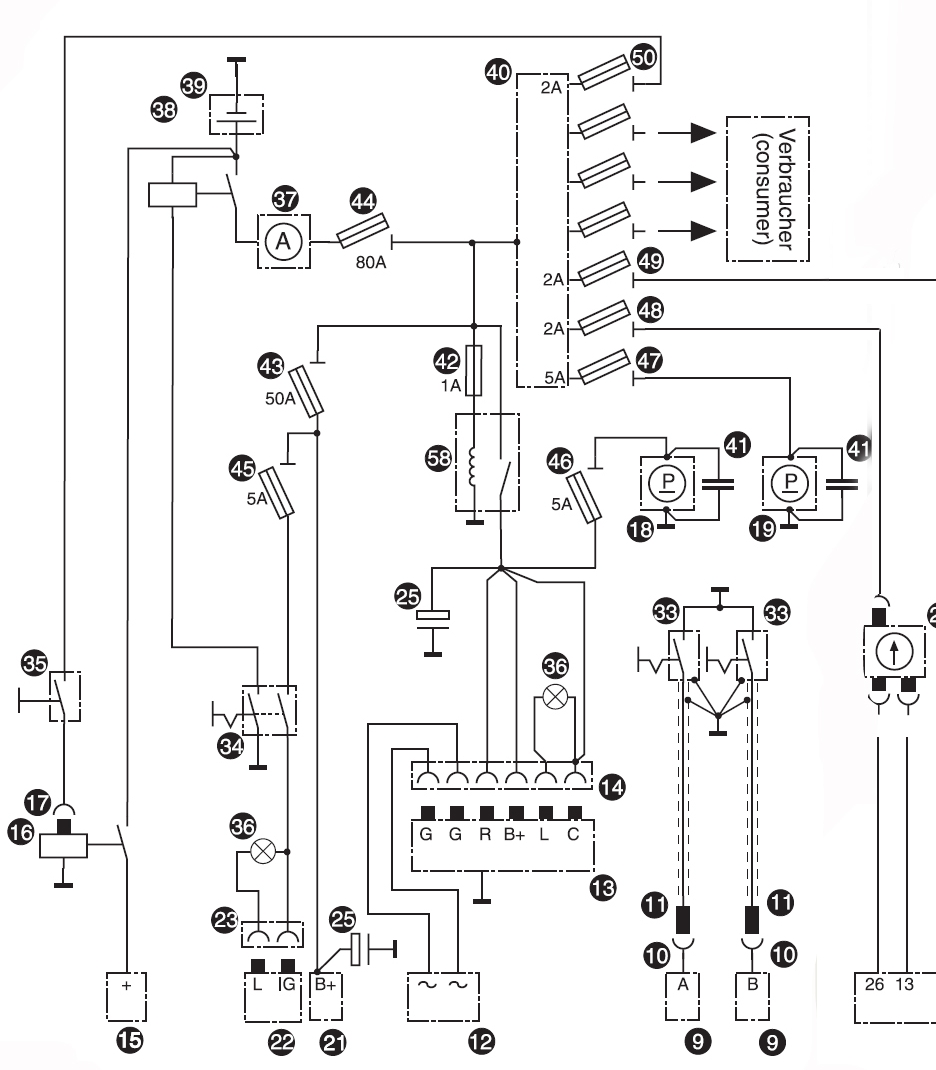

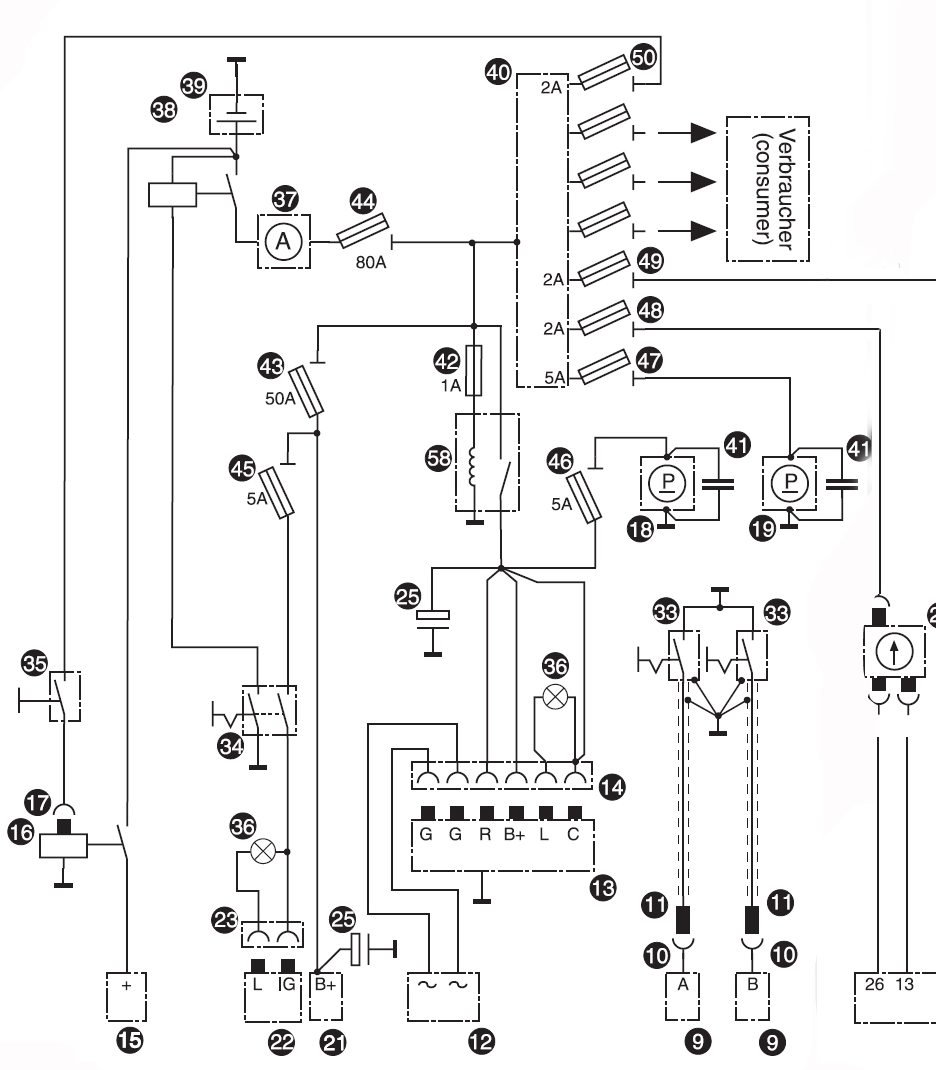

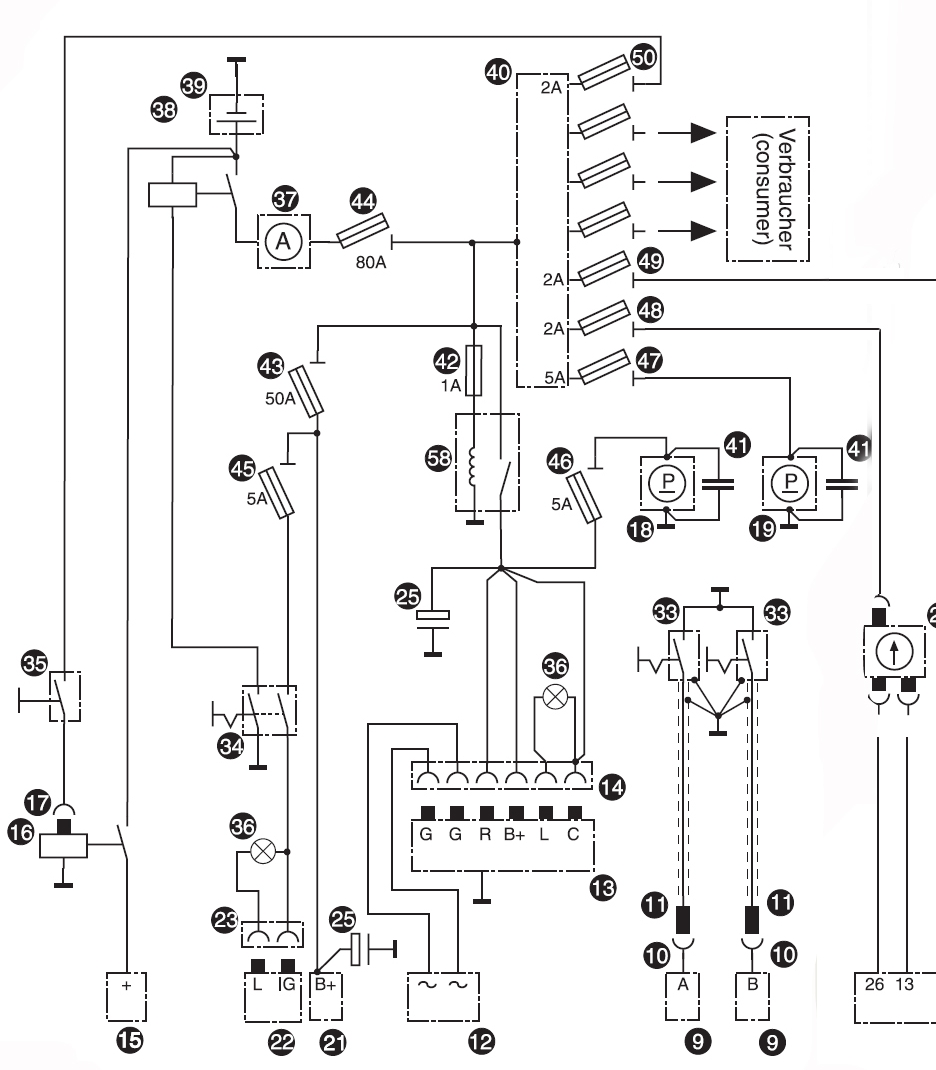

| Quote: | Rick, It's the wiring diagram from the Installation Manual for the 914.

On Mon, Nov 24, 2014 at 7:08 PM, Richard Girard <aslsa.rng(at)gmail.com (aslsa.rng(at)gmail.com)> wrote:

| Quote: | Ken, I've been off the forum for a few weeks and just saw your request for info on the Rotax alternator (dynamo). Can you quote chapter and verse of the manual you are referencing? One of my custormers has a 912 in a JA Highlander that was down for months fixing a long list of defects found during the annual conditional inspection and the battery started the engine just fine when we were done. The 582 on my Kolb has the same basic alternator. I did a major rebuild on the airplane and it was down for over 18 months. The engine started right up when I took it out and that was with a five year old 18 AH  SLA battery.

Rick Girard

On Wed, Nov 12, 2014 at 12:47 PM, Ken Ryan <keninalaska(at)gmail.com (keninalaska(at)gmail.com)> wrote:

| Quote: | Thanks Bob,

I was wondering about that 80 amp fuse. It seems better to connect the bus directly to the battery. With regards to the 1 amp fuse that you say is unnecessary, why do you say that? Isn't it there to protect the wire that runs from the battery to relay 58? I think the reasoning behind wiring one fuel pump to the generator, is because the 914 relies on an electric fuel pump, and they are trying to provide two independent power sources for each pump.

On Wed, Nov 12, 2014 at 9:18 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | At 11:01 2014-11-12, you wrote:

| Quote: | | Thanks Bob. I do have the book. I am building a Just Aircraft SuperSTOL. A previous lister said that the IG wire from the external alternator needs to be disconnected to avoid drawing down the battery, which it is on the Rotax diagram (via the master switch). Are you saying that you disagree with this and that the IG wired does not need to be disconnected to avoid drawing down the battery? |

Ooops . . . sorry 'bout that. We're talking about the wound-field

alternator . . . not the PM machine. That light doesn't work with much more

intelligence than that annunciator on the PM rectifier/regulator.

It's definitely dark when the alternator is working but may

not light when the alternator is inadequate to system

needs. I don't use those outputs either.

If you're planning on ACTIVE NOTIFICATION OF LOW VOLTS then

you can simply leave the light off the panel and leave the

terminal disconnected.

But you're correct, when wired per the Rotax drawing, IG gets

disconnected when the big-alternator switch is OFF . . . so if

you plan to use the light, wired as shown eliminates the

concern.

An interesting feature of their wiring gives you no control

over the little alternator . . . it is automatically switched

ON via relay (5 with an unnecessary, 1A fuse in the coil with an unnecessary, 1A fuse in the coil

lead. This relay closes as soon as you turn on the master

switch and will stay closed as long as the engine is running

even if battery relay (3 is opened. Bringing engine is opened. Bringing engine

rpm down will slowly drop voltage on the bus . . . and

might cause the little-alternator relay to drop but

this raises all kinds of questions about the behaviors

of the ship's accessories.

The relay will certainly drop after the engine is shut

down.

Another interesting feature uses the little-alternator

output to power up one of two fuel pumps whether or not

the master switch is ON.

The 80A breaker is, in US TC aircraft philosophy, not

necessary or useful.

[img]cid:.0[/img]Â Â Â Â Â Â Â Â

Bob . . .

|

|

--

Believe those who are seeking the truth, doubt those who find it.

-Andre Gide

|

|

--

Believe those who are seeking the truth, doubt those who find it.

-Andre Gide

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

274.22 KB |

| Viewed: |

11485 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Nov 27, 2014 8:05 am Post subject: alternator / generator Posted: Thu Nov 27, 2014 8:05 am Post subject: alternator / generator |

|

|

At 03:12 PM 11/26/2014, you wrote:

That's a LOT of hardware for what would otherwise be

a simple system.

What are your anticipated missions that would benefit

from dual batteries and the automation offered by

the Bus Manager? Your continuous loads are minimal.

Even the 3.2A value for the radio is probably more like

0.2A receive, 3.2A transmit . . . which pushes its

energy requirements down to insignificant . . . about

1/4th power it takes to keep one battery contactor

closed.

How, and under what circumstances, would dual batteries

mitigate perceived risks for the operation of your

system?

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 429

|

Posted: Thu Nov 27, 2014 9:00 am Post subject: alternator / generator Posted: Thu Nov 27, 2014 9:00 am Post subject: alternator / generator |

|

|

Being in Alaska, many landings are remote, off airport. The engine must start. If it doesn't the only option is to trigger search and rescue. Two batteries mitigates the risk of the engine not starting 150 miles from the nearest civilization.

How, and under what circumstances, would dual batteries  mitigate perceived risks for the operation of your system?

Bob . . .

On Thu, Nov 27, 2014 at 6:51 AM, Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

[quote] At 03:12 PM 11/26/2014, you wrote:

That's a LOT of hardware for what would otherwise be

a simple system.

What are your anticipated missions that would benefit

from dual batteries and the automation offered by

the Bus Manager? Your continuous loads are minimal.

Even the 3.2A value for the radio is probably more like

0.2A receive, 3.2A transmit . . . which pushes its

energy requirements down to insignificant . . . about

1/4th power it takes to keep one battery contactor

closed.

How, and under what circumstances, would dual batteries

mitigate perceived risks for the operation of your

system?

Bob . . . | Quote: |

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

="_blank">www.mypilotstore.com

ank">www.mrrace.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

tp://forums.matronics.com

|

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Nov 27, 2014 10:49 am Post subject: alternator / generator Posted: Thu Nov 27, 2014 10:49 am Post subject: alternator / generator |

|

|

At 10:58 AM 11/27/2014, you wrote:

| Quote: | | Being in Alaska, many landings are remote, off airport. The engine must start. If it doesn't the only option is to trigger search and rescue. Two batteries mitigates the risk of the engine not starting 150 miles from the nearest civilization. |

Okay, how often has the 'unavailable battery' syndrome

presented itself . . . and what was root cause for the

failure?

A battery can and should be the single most reliable

source of energy on your airplane. This presumes, of

course, that you give it the same level of attention

to airworthiness that is bestowed upon fuel, oil, tires,

continuity of flight controls, fuel filters and sumps,

prop blade nicks, etc. etc.

Batteries tend to be the oft neglected step-child

of flight systems. The predominant public perception

of battery consumerism is to run it until it wont

crank the engine any more . . . Walmart sells

a gizillion batteries every year that are replaced

in response to that same symptom.

Some years ago I corresponded with a Cessna 206

floatplane owner in S. America who was wanting to add a

second battery to his ship. We pondered useful volume

to exploit for several exchanges of e-mails. We

finally decided that inside one of the floats was

the best location. The battery could be positioned

right on C.G. and it occupied volume that had

no other purpose.

After we had corresponded a few times, he agreed

that his REAL worry was for loss of a battery contactor.

He conceded that in the grand scheme of things,

battery maintenance was not a big adder to cost-of-

ownership, his big worry was for loss of battery

contactor that would make the battery unavailable.

I suggested then than he add a piece of welding cable

to run from downstream side of battery contactor to

the battery box (accessible while standing on a

float). Should preflight testing before tossing

the mooring lines showed that the battery contactor was

"iffy", he could make a manual connection to the

battery (+) terminal with the short jumper.

He decided that was a much less expensive, lighter

and lower cost plan-C for dealing with a failed

battery contactor. We also discussed simply carrying

a spare contactor and tools . . . but that didn't

cover the potential loss of wiring and/or battery

master switch. So he opted for the jumper-cable

and a pair of pliers.

The point to ponder is how best to accommodate or

modify a system that is a direct descendant from

systems common to garden tractors: PM alternator,

simple rectifier/regulator and a lead acid battery.

It seems that the elegant design goal is to craft

a combination of architecture, preventive maintenance\

and operating procedures that accommodates low risk failures

-OR- drives specific failure rates down to insignificance.

I believe this can be achieved without adding the

weight, cost or complexity of burdening a

garden-tractor-style electrical system with

concepts holy-watered by the FAA and embraced

by Boeing and Airbus.

This requires a simple but thorough thought

process that goes through the steps of considering

EVERY part of your electrical system from crimped

terminals to alternators and batteries.

How can this part fail?

Is failure pre-flight detectable?

If it fails in flight, how will I know about

it?

How would in-flight failure affect comfortable

termination of flight?

What are the lowest cost, lightest weight,

simplest mitigations for the failure?

Due diligence to Failure Mode Effects Analysis

(FMEA) offers the short-path to the simpler,

lightest weight, lowest cost, lowest risk

(elegant) design easily understood and managed by the

cognizant pilot.

Bob . . . [quote][b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

kenryan

Joined: 20 Oct 2009

Posts: 429

|

Posted: Thu Nov 27, 2014 11:32 am Post subject: alternator / generator Posted: Thu Nov 27, 2014 11:32 am Post subject: alternator / generator |

|

|

An argument can be made both for and against the second battery. I have considered both and determined that in my case the extra battery is justified. Your points are nevertheless well taken. On Nov 27, 2014 10:54 AM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:[quote] At 10:58 AM 11/27/2014, you wrote:

| Quote: | | Being in Alaska, many landings are remote, off airport. The engine must start. If it doesn't the only option is to trigger search and rescue. Two batteries mitigates the risk of the engine not starting 150 miles from the nearest civilization. |

Okay, how often has the 'unavailable battery' syndrome

presented itself . . . and what was root cause for the

failure?

A battery can and should be the single most reliable

source of energy on your airplane. This presumes, of

course, that you give it the same level of attention

to airworthiness that is bestowed upon fuel, oil, tires,

continuity of flight controls, fuel filters and sumps,

prop blade nicks, etc. etc.

Batteries tend to be the oft neglected step-child

of flight systems. The predominant public perception

of battery consumerism is to run it until it wont

crank the engine any more . . . Walmart sells

a gizillion batteries every year that are replaced

in response to that same symptom.

Some years ago I corresponded with a Cessna 206

floatplane owner in S. America who was wanting to add a

second battery to his ship. We pondered useful volume

to exploit for several exchanges of e-mails. We

finally decided that inside one of the floats was

the best location. The battery could be positioned

right on C.G. and it occupied volume that had

no other purpose.

After we had corresponded a few times, he agreed

that his REAL worry was for loss of a battery contactor.

He conceded that in the grand scheme of things,

battery maintenance was not a big adder to cost-of-

ownership, his big worry was for loss of battery

contactor that would make the battery unavailable.

I suggested then than he add a piece of welding cable

to run from downstream side of battery contactor to

the battery box (accessible while standing on a

float). Should preflight testing before tossing

the mooring lines showed that the battery contactor was

"iffy", he could make a manual connection to the

battery (+) terminal with the short jumper.

He decided that was a much less expensive, lighter

and lower cost plan-C for dealing with a failed

battery contactor. We also discussed simply carrying

a spare contactor and tools . . . but that didn't

cover the potential loss of wiring and/or battery

master switch. So he opted for the jumper-cable

and a pair of pliers.

The point to ponder is how best to accommodate or

modify a system that is a direct descendant from

systems common to garden tractors: PM alternator,

simple rectifier/regulator and a lead acid battery.

It seems that the elegant design goal is to craft

a combination of architecture, preventive maintenance\

and operating procedures that accommodates low risk failures

-OR- drives specific failure rates down to insignificance.

I believe this can be achieved without adding the

weight, cost or complexity of burdening a

garden-tractor-style electrical system with

concepts holy-watered by the FAA and embraced

by Boeing and Airbus.

This requires a simple but thorough thought

process that goes through the steps of considering

EVERY part of your electrical system from crimped

terminals to alternators and batteries.

How can this part fail?

Is failure pre-flight detectable?

If it fails in flight, how will I know about

it?

How would in-flight failure affect comfortable

termination of flight?

What are the lowest cost, lightest weight,

simplest mitigations for the failure?

Due diligence to Failure Mode Effects Analysis

(FMEA) offers the short-path to the simpler,

lightest weight, lowest cost, lowest risk

(elegant) design easily understood and managed by the

cognizant pilot.

Bob . . . | Quote: |

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

="_blank">www.mypilotstore.com

ank">www.mrrace.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

tp://forums.matronics.com

|

[b]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1706

Location: Sun Lakes AZ

|

Posted: Thu Nov 27, 2014 12:11 pm Post subject: alternator / generator Posted: Thu Nov 27, 2014 12:11 pm Post subject: alternator / generator |

|

|

Well, having flown for 20 yrs in Alaska, I would take starter motor

failure as a higher risk than battery failure. Adding electronic

ignition to a plane in that environment IMHO adds risk over a dead

simple pair of magnetos. Most of time there is a means to hand prop if

lack of battery presents itself. Needing electrons to fire the ignition

as well as crank the engine creates more potential risk.

On 11/27/2014 12:32 PM, Ken Ryan wrote:

| Quote: |

An argument can be made both for and against the second battery. I

have considered both and determined that in my case the extra battery

is justified. Your points are nevertheless well taken.

On Nov 27, 2014 10:54 AM, "Robert L. Nuckolls, III"

<nuckolls.bob(at)aeroelectric.com <mailto:nuckolls.bob(at)aeroelectric.com>>

wrote:

At 10:58 AM 11/27/2014, you wrote:

> Being in Alaska, many landings are remote, off airport. The

> engine must start. If it doesn't the only option is to trigger

> search and rescue. Two batteries mitigates the risk of the engine

> not starting 150 miles from the nearest civilization.

Okay, how often has the 'unavailable battery' syndrome

presented itself . . . and what was root cause for the

failure?

A battery can and should be the single most reliable

source of energy on your airplane. This presumes, of

course, that you give it the same level of attention

to airworthiness that is bestowed upon fuel, oil, tires,

continuity of flight controls, fuel filters and sumps,

prop blade nicks, etc. etc.

Batteries tend to be the oft neglected step-child

of flight systems. The predominant public perception

of battery consumerism is to run it until it wont

crank the engine any more . . . Walmart sells

a gizillion batteries every year that are replaced

in response to that same symptom.

Some years ago I corresponded with a Cessna 206

floatplane owner in S. America who was wanting to add a

second battery to his ship. We pondered useful volume

to exploit for several exchanges of e-mails. We

finally decided that inside one of the floats was

the best location. The battery could be positioned

right on C.G. and it occupied volume that had

no other purpose.

After we had corresponded a few times, he agreed

that his REAL worry was for loss of a battery contactor.

He conceded that in the grand scheme of things,

battery maintenance was not a big adder to cost-of-

ownership, his big worry was for loss of battery

contactor that would make the battery unavailable.

I suggested then than he add a piece of welding cable

to run from downstream side of battery contactor to

the battery box (accessible while standing on a

float). Should preflight testing before tossing

the mooring lines showed that the battery contactor was

"iffy", he could make a manual connection to the

battery (+) terminal with the short jumper.

He decided that was a much less expensive, lighter

and lower cost plan-C for dealing with a failed

battery contactor. We also discussed simply carrying

a spare contactor and tools . . . but that didn't

cover the potential loss of wiring and/or battery

master switch. So he opted for the jumper-cable

and a pair of pliers.

The point to ponder is how best to accommodate or

modify a system that is a direct descendant from

systems common to garden tractors: PM alternator,

simple rectifier/regulator and a lead acid battery.

It seems that the elegant design goal is to craft

a combination of architecture, preventive maintenance\

and operating procedures that accommodates low risk failures

-OR- drives specific failure rates down to insignificance.

I believe this can be achieved without adding the

weight, cost or complexity of burdening a

garden-tractor-style electrical system with

concepts holy-watered by the FAA and embraced

by Boeing and Airbus.

This requires a simple but thorough thought

process that goes through the steps of considering

EVERY part of your electrical system from crimped

terminals to alternators and batteries.

How can this part fail?

Is failure pre-flight detectable?

If it fails in flight, how will I know about

it?

How would in-flight failure affect comfortable

termination of flight?

What are the lowest cost, lightest weight,

simplest mitigations for the failure?

Due diligence to Failure Mode Effects Analysis

(FMEA) offers the short-path to the simpler,

lightest weight, lowest cost, lowest risk

(elegant) design easily understood and managed by the

cognizant pilot.

Bob . . .

*

_blank">www.aeroelectric.com

.com" target="_blank">www.buildersbooks.com

="_blank">www.homebuilthelp.com

="_blank">www.mypilotstore.com

ank">www.mrrace.com

_blank">http://www.matronics.com/contribution

ist" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

tp://forums.matronics.com

*

*

*

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

jmjones2000(at)mindspring

Guest

|

Posted: Thu Nov 27, 2014 1:06 pm Post subject: alternator / generator Posted: Thu Nov 27, 2014 1:06 pm Post subject: alternator / generator |

|

|

I also fly in Alaska. I agree that a battery failure isnât as likely as a starter failure, but if having two batteries on the aircraft is an acceptable risk mitigation step for him, then he is justified having the extra battery. I will have two alternators. One gear driven and one belt driven. I will also carry a battery jump starter pack and a solar cell that is capable of charging it when I plan on spending any time in the bush. I understand the added weight of the pack, however after using it just a single time, it will have been worth it. If my starter does die and the battery still has at least 6 volts (EFII system minimum), the ignition and injection systems will still operate, making hand propping much easier than a healthy magneto. I will still need enough voltage to excite the alternator for continued 12v operation. One pass of the flywheel magnets past the crank trigger should start the engine.

I disagree with the statement that electronic ignition adds risk. There are many reasons.

1st reason is the massive amount of time electric ignition has been in operation. Nearly every vehicle manufactured since the mid 70s has electronic ignition, meaning there are MANY MANY more hours of operation on electronic ignition units than magnetos. They have been proven VERY reliable and need very little maintenance.

2nd reason is there are solid state units that require no moving parts (crank trigger systems). It is true that there are different electric systems out there, however they all run on the same principal. There are also redundant systems available that can keep the engine running in the extremely unlikely event that one fails. Choose the one that is satisfactory to you and go with it.

3rd reason that electronic ignition doesnât add risk is the complexity and unreliability of magnetos. They have moving parts that wear. They have TBOs on them because they are known to wear and malfunction. They are heavy, expensive, and do not provide the same amount of energy that an electronic ignition does. I have personally had 3 magneto failures. Thankfully both have never quit on me at once. A good friend in a Maule M4 just had one fail last week.

4th reason is the correct 12v system architecture that electronic ignition requires is very reliable. The Z-diagrams that Bob has authored have the capability to mitigate most risk involved with the 12v system. I have personally chosen to go with a dual alternator system. I will carry small light solar panels that can recharge a battery in a matter of days.

There is a good compromise out there. Look at the G3i ignition system. It adds an MSD electronic ignition box and runs it through the magneto (if you feel that you MUST have the unreliable mags). If the MSD box fails or if the battery dies, the magnetos will still act like magnetos.

The thing to keep in mind regardless of how many batteries that you have on the aircraft is watching your battery health. If your battery or batteries show any sign of ill health, replace them. Donât push it. Batteries seldom fail overnight. Some people even replace them every annual.

I feel that a properly installed and maintained redundant electronic ignition system will actually REDUCE the risk that the legacy magneto systems offer.

Respectfully,

Justin

| Quote: | On Nov 27, 2014, at 11:10 AM, Kelly McMullen <kellym(at)aviating.com> wrote:

Well, having flown for 20 yrs in Alaska, I would take starter motor failure as a higher risk than battery failure. Adding electronic ignition to a plane in that environment IMHO adds risk over a dead simple pair of magnetos. Most of time there is a means to hand prop if lack of battery presents itself. Needing electrons to fire the ignition as well as crank the engine creates more potential risk.

On 11/27/2014 12:32 PM, Ken Ryan wrote:

>

> An argument can be made both for and against the second battery. I have considered both and determined that in my case the extra battery is justified. Your points are nevertheless well taken.

>

> On Nov 27, 2014 10:54 AM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com <mailto:nuckolls.bob(at)aeroelectric.com>> wrote:

>

> At 10:58 AM 11/27/2014, you wrote:

>> Being in Alaska, many landings are remote, off airport. The

>> engine must start. If it doesn't the only option is to trigger

>> search and rescue. Two batteries mitigates the risk of the engine

>> not starting 150 miles from the nearest civilization.

>

>

> Okay, how often has the 'unavailable battery' syndrome

> presented itself . . . and what was root cause for the

> failure?

>

> A battery can and should be the single most reliable

> source of energy on your airplane. This presumes, of

> course, that you give it the same level of attention

> to airworthiness that is bestowed upon fuel, oil, tires,

> continuity of flight controls, fuel filters and sumps,

> prop blade nicks, etc. etc.

>

> Batteries tend to be the oft neglected step-child

> of flight systems. The predominant public perception

> of battery consumerism is to run it until it wont

> crank the engine any more . . . Walmart sells

> a gizillion batteries every year that are replaced

> in response to that same symptom.

>

> Some years ago I corresponded with a Cessna 206

> floatplane owner in S. America who was wanting to add a

> second battery to his ship. We pondered useful volume

> to exploit for several exchanges of e-mails. We

> finally decided that inside one of the floats was

> the best location. The battery could be positioned

> right on C.G. and it occupied volume that had

> no other purpose.

>

> After we had corresponded a few times, he agreed

> that his REAL worry was for loss of a battery contactor.

> He conceded that in the grand scheme of things,

> battery maintenance was not a big adder to cost-of-

> ownership, his big worry was for loss of battery

> contactor that would make the battery unavailable.

>

> I suggested then than he add a piece of welding cable

> to run from downstream side of battery contactor to

> the battery box (accessible while standing on a

> float). Should preflight testing before tossing

> the mooring lines showed that the battery contactor was

> "iffy", he could make a manual connection to the

> battery (+) terminal with the short jumper.

>

> He decided that was a much less expensive, lighter

> and lower cost plan-C for dealing with a failed

> battery contactor. We also discussed simply carrying

> a spare contactor and tools . . . but that didn't

> cover the potential loss of wiring and/or battery

> master switch. So he opted for the jumper-cable

> and a pair of pliers.

>

> The point to ponder is how best to accommodate or

> modify a system that is a direct descendant from

> systems common to garden tractors: PM alternator,

> simple rectifier/regulator and a lead acid battery.

>

> It seems that the elegant design goal is to craft

> a combination of architecture, preventive maintenance\

> and operating procedures that accommodates low risk failures

> -OR- drives specific failure rates down to insignificance.

>

> I believe this can be achieved without adding the

> weight, cost or complexity of burdening a

> garden-tractor-style electrical system with

> concepts holy-watered by the FAA and embraced

> by Boeing and Airbus.

>

> This requires a simple but thorough thought

> process that goes through the steps of considering

> EVERY part of your electrical system from crimped

> terminals to alternators and batteries.

>

> How can this part fail?

>

> Is failure pre-flight detectable?

>

> If it fails in flight, how will I know about

> it?

>

> How would in-flight failure affect comfortable

> termination of flight?

>

> What are the lowest cost, lightest weight,

> simplest mitigations for the failure?

>

> Due diligence to Failure Mode Effects Analysis

> (FMEA) offers the short-path to the simpler,

> lightest weight, lowest cost, lowest risk

> (elegant) design easily understood and managed by the

> cognizant pilot.

>

> Bob . . .

>

> *

>

> _blank">www.aeroelectric.com

> .com" target="_blank">www.buildersbooks.com

> ="_blank">www.homebuilthelp.com

> ="_blank">www.mypilotstore.com

> ank">www.mrrace.com

> _blank">http://www.matronics.com/contribution

> ist" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

> tp://forums.matronics.com

>

> *

>

> *

>

>

> *

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

Kellym

Joined: 10 Jan 2006

Posts: 1706

Location: Sun Lakes AZ

|

Posted: Thu Nov 27, 2014 1:16 pm Post subject: alternator / generator Posted: Thu Nov 27, 2014 1:16 pm Post subject: alternator / generator |

|

|

Well, I had two electronic ignitions stone cold fail in Alaska. One at

40 below. The other in summer, but just as inconvenient. You don't hear

about the failures much because they just pull over to roadside and call

a tow truck. Typically when they fail it is a hard failure, not just

rough running like a mag on its way out. I may install electronic in

place of one mag, but definitely not two.

On 11/27/2014 2:04 PM, Justin Jones wrote:

| Quote: |

I also fly in Alaska. I agree that a battery failure isnât as likely as a starter failure, but if having two batteries on the aircraft is an acceptable risk mitigation step for him, then he is justified having the extra battery. I will have two alternators. One gear driven and one belt driven. I will also carry a battery jump starter pack and a solar cell that is capable of charging it when I plan on spending any time in the bush. I understand the added weight of the pack, however after using it just a single time, it will have been worth it. If my starter does die and the battery still has at least 6 volts (EFII system minimum), the ignition and injection systems will still operate, making hand propping much easier than a healthy magneto. I will still need enough voltage to excite the alternator for continued 12v operation. One pass of the flywheel magnets past the crank trigger should start the engine.

I disagree with the statement that electronic ignition adds risk. There are many reasons.

1st reason is the massive amount of time electric ignition has been in operation. Nearly every vehicle manufactured since the mid 70s has electronic ignition, meaning there are MANY MANY more hours of operation on electronic ignition units than magnetos. They have been proven VERY reliable and need very little maintenance.

2nd reason is there are solid state units that require no moving parts (crank trigger systems). It is true that there are different electric systems out there, however they all run on the same principal. There are also redundant systems available that can keep the engine running in the extremely unlikely event that one fails. Choose the one that is satisfactory to you and go with it.

3rd reason that electronic ignition doesnât add risk is the complexity and unreliability of magnetos. They have moving parts that wear. They have TBOs on them because they are known to wear and malfunction. They are heavy, expensive, and do not provide the same amount of energy that an electronic ignition does. I have personally had 3 magneto failures. Thankfully both have never quit on me at once. A good friend in a Maule M4 just had one fail last week.

4th reason is the correct 12v system architecture that electronic ignition requires is very reliable. The Z-diagrams that Bob has authored have the capability to mitigate most risk involved with the 12v system. I have personally chosen to go with a dual alternator system. I will carry small light solar panels that can recharge a battery in a matter of days.

There is a good compromise out there. Look at the G3i ignition system. It adds an MSD electronic ignition box and runs it through the magneto (if you feel that you MUST have the unreliable mags). If the MSD box fails or if the battery dies, the magnetos will still act like magnetos.

The thing to keep in mind regardless of how many batteries that you have on the aircraft is watching your battery health. If your battery or batteries show any sign of ill health, replace them. Donât push it. Batteries seldom fail overnight. Some people even replace them every annual.

I feel that a properly installed and maintained redundant electronic ignition system will actually REDUCE the risk that the legacy magneto systems offer.

Respectfully,

Justin

> On Nov 27, 2014, at 11:10 AM, Kelly McMullen <kellym(at)aviating.com> wrote:

>

>

>

|

| Quote: | > Well, having flown for 20 yrs in Alaska, I would take starter motor failure as a higher risk than battery failure. Adding electronic ignition to a plane in that environment IMHO adds risk over a dead simple pair of magnetos. Most of time there is a means to hand prop if lack of battery presents itself. Needing electrons to fire the ignition as well as crank the engine creates more potential risk.

>

> On 11/27/2014 12:32 PM, Ken Ryan wrote:

>> An argument can be made both for and against the second battery. I have considered both and determined that in my case the extra battery is justified. Your points are nevertheless well taken.

>>

>> On Nov 27, 2014 10:54 AM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com <mailto:nuckolls.bob(at)aeroelectric.com>> wrote:

>>

>> At 10:58 AM 11/27/2014, you wrote:

>>> Being in Alaska, many landings are remote, off airport. The

>>> engine must start. If it doesn't the only option is to trigger

>>> search and rescue. Two batteries mitigates the risk of the engine

>>> not starting 150 miles from the nearest civilization.

>>

>> Okay, how often has the 'unavailable battery' syndrome

>> presented itself . . . and what was root cause for the

>> failure?

>>

>> A battery can and should be the single most reliable

>> source of energy on your airplane. This presumes, of

>> course, that you give it the same level of attention

>> to airworthiness that is bestowed upon fuel, oil, tires,

>> continuity of flight controls, fuel filters and sumps,

>> prop blade nicks, etc. etc.

>>

>> Batteries tend to be the oft neglected step-child

>> of flight systems. The predominant public perception

>> of battery consumerism is to run it until it wont

>> crank the engine any more . . . Walmart sells

>> a gizillion batteries every year that are replaced

>> in response to that same symptom.

>>

>> Some years ago I corresponded with a Cessna 206

>> floatplane owner in S. America who was wanting to add a

>> second battery to his ship. We pondered useful volume

>> to exploit for several exchanges of e-mails. We

>> finally decided that inside one of the floats was

>> the best location. The battery could be positioned

>> right on C.G. and it occupied volume that had

>> no other purpose.

>>

>> After we had corresponded a few times, he agreed

>> that his REAL worry was for loss of a battery contactor.

>> He conceded that in the grand scheme of things,

>> battery maintenance was not a big adder to cost-of-

>> ownership, his big worry was for loss of battery

>> contactor that would make the battery unavailable.

>>

>> I suggested then than he add a piece of welding cable

>> to run from downstream side of battery contactor to

>> the battery box (accessible while standing on a

>> float). Should preflight testing before tossing

>> the mooring lines showed that the battery contactor was

>> "iffy", he could make a manual connection to the

>> battery (+) terminal with the short jumper.

>>

>> He decided that was a much less expensive, lighter

>> and lower cost plan-C for dealing with a failed

>> battery contactor. We also discussed simply carrying

>> a spare contactor and tools . . . but that didn't

>> cover the potential loss of wiring and/or battery

>> master switch. So he opted for the jumper-cable

>> and a pair of pliers.

>>

>> The point to ponder is how best to accommodate or

>> modify a system that is a direct descendant from

>> systems common to garden tractors: PM alternator,

>> simple rectifier/regulator and a lead acid battery.

>>

>> It seems that the elegant design goal is to craft

>> a combination of architecture, preventive maintenance\

>> and operating procedures that accommodates low risk failures

>> -OR- drives specific failure rates down to insignificance.

>>

>> I believe this can be achieved without adding the

>> weight, cost or complexity of burdening a

>> garden-tractor-style electrical system with

>> concepts holy-watered by the FAA and embraced

>> by Boeing and Airbus.

>>

>> This requires a simple but thorough thought

>> process that goes through the steps of considering

>> EVERY part of your electrical system from crimped

>> terminals to alternators and batteries.

>>

>> How can this part fail?

>>

>> Is failure pre-flight detectable?

>>

>> If it fails in flight, how will I know about

>> it?

>>

>> How would in-flight failure affect comfortable

>> termination of flight?

>>

>> What are the lowest cost, lightest weight,

>> simplest mitigations for the failure?

>>

>> Due diligence to Failure Mode Effects Analysis

>> (FMEA) offers the short-path to the simpler,

>> lightest weight, lowest cost, lowest risk

>> (elegant) design easily understood and managed by the

>> cognizant pilot.

>>

>> Bob . . .

>>

>> *

>>

>> _blank">www.aeroelectric.com

>> .com" target="_blank">www.buildersbooks.com

>> ="_blank">www.homebuilthelp.com

>> ="_blank">www.mypilotstore.com

>> ank">www.mrrace.com

>> _blank">http://www.matronics.com/contribution

>> ist" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

>> tp://forums.matronics.com

>>

>> *

>>

>> *

>>

>>

>> *

>

>

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Kelly McMullen

A&P/IA, EAA Tech Counselor # 5286

KCHD |

|

| Back to top |

|

|

jmjones2000(at)mindspring

Guest

|

Posted: Thu Nov 27, 2014 1:39 pm Post subject: alternator / generator Posted: Thu Nov 27, 2014 1:39 pm Post subject: alternator / generator |

|

|

Nothing that we do in aviation, experimental aviation especially, is without risk. It is merely a game of acceptable risk. For me, having 2 independent and completely redundant electronic ignition units provides an acceptable level of risk. This is because there isnât a single point of failure in the system. I feel that the benefit of having both electronic units is the added performance of an adaptable timing curve and a much hotter spark. Others, such as yourself, feel comfortable with one electronic unit and one magneto. Both are correct because the system meets the designerâs acceptable amount of risk and both for different reasons.

Cheers

Justin

| Quote: | On Nov 27, 2014, at 12:15 PM, Kelly McMullen <kellym(at)aviating.com> wrote:

Well, I had two electronic ignitions stone cold fail in Alaska. One at 40 below. The other in summer, but just as inconvenient. You don't hear about the failures much because they just pull over to roadside and call a tow truck. Typically when they fail it is a hard failure, not just rough running like a mag on its way out. I may install electronic in place of one mag, but definitely not two.

On 11/27/2014 2:04 PM, Justin Jones wrote:

>

>

> I also fly in Alaska. I agree that a battery failure isnât as likely as a starter failure, but if having two batteries on the aircraft is an acceptable risk mitigation step for him, then he is justified having the extra battery. I will have two alternators. One gear driven and one belt driven. I will also carry a battery jump starter pack and a solar cell that is capable of charging it when I plan on spending any time in the bush. I understand the added weight of the pack, however after using it just a single time, it will have been worth it. If my starter does die and the battery still has at least 6 volts (EFII system minimum), the ignition and injection systems will still operate, making hand propping much easier than a healthy magneto. I will still need enough voltage to excite the alternator for continued 12v operation. One pass of the flywheel magnets past the crank trigger should start the engine.

>

> I disagree with the statement that electronic ignition adds risk. There are many reasons.

>

> 1st reason is the massive amount of time electric ignition has been in operation. Nearly every vehicle manufactured since the mid 70s has electronic ignition, meaning there are MANY MANY more hours of operation on electronic ignition units than magnetos. They have been proven VERY reliable and need very little maintenance.

>

> 2nd reason is there are solid state units that require no moving parts (crank trigger systems). It is true that there are different electric systems out there, however they all run on the same principal. There are also redundant systems available that can keep the engine running in the extremely unlikely event that one fails. Choose the one that is satisfactory to you and go with it.

>

> 3rd reason that electronic ignition doesnât add risk is the complexity and unreliability of magnetos. They have moving parts that wear. They have TBOs on them because they are known to wear and malfunction. They are heavy, expensive, and do not provide the same amount of energy that an electronic ignition does. I have personally had 3 magneto failures. Thankfully both have never quit on me at once. A good friend in a Maule M4 just had one fail last week.

>

> 4th reason is the correct 12v system architecture that electronic ignition requires is very reliable. The Z-diagrams that Bob has authored have the capability to mitigate most risk involved with the 12v system. I have personally chosen to go with a dual alternator system. I will carry small light solar panels that can recharge a battery in a matter of days.

>

> There is a good compromise out there. Look at the G3i ignition system. It adds an MSD electronic ignition box and runs it through the magneto (if you feel that you MUST have the unreliable mags). If the MSD box fails or if the battery dies, the magnetos will still act like magnetos.

>

> The thing to keep in mind regardless of how many batteries that you have on the aircraft is watching your battery health. If your battery or batteries show any sign of ill health, replace them. Donât push it. Batteries seldom fail overnight. Some people even replace them every annual.

>

> I feel that a properly installed and maintained redundant electronic ignition system will actually REDUCE the risk that the legacy magneto systems offer.

>

> Respectfully,

>

> Justin

>

>

>> On Nov 27, 2014, at 11:10 AM, Kelly McMullen <kellym(at)aviating.com> wrote:

>>

>>

>>

>> Well, having flown for 20 yrs in Alaska, I would take starter motor failure as a higher risk than battery failure. Adding electronic ignition to a plane in that environment IMHO adds risk over a dead simple pair of magnetos. Most of time there is a means to hand prop if lack of battery presents itself. Needing electrons to fire the ignition as well as crank the engine creates more potential risk.

>>

>> On 11/27/2014 12:32 PM, Ken Ryan wrote:

>>> An argument can be made both for and against the second battery. I have considered both and determined that in my case the extra battery is justified. Your points are nevertheless well taken.

>>>

>>> On Nov 27, 2014 10:54 AM, "Robert L. Nuckolls, III" <nuckolls.bob(at)aeroelectric.com <mailto:nuckolls.bob(at)aeroelectric.com>> wrote:

>>>

>>> At 10:58 AM 11/27/2014, you wrote:

>>>> Being in Alaska, many landings are remote, off airport. The

>>>> engine must start. If it doesn't the only option is to trigger

>>>> search and rescue. Two batteries mitigates the risk of the engine

>>>> not starting 150 miles from the nearest civilization.

>>>

>>> Okay, how often has the 'unavailable battery' syndrome

>>> presented itself . . . and what was root cause for the

>>> failure?

>>>

>>> A battery can and should be the single most reliable

>>> source of energy on your airplane. This presumes, of

>>> course, that you give it the same level of attention

>>> to airworthiness that is bestowed upon fuel, oil, tires,

>>> continuity of flight controls, fuel filters and sumps,

>>> prop blade nicks, etc. etc.

>>>

>>> Batteries tend to be the oft neglected step-child

>>> of flight systems. The predominant public perception

>>> of battery consumerism is to run it until it wont

>>> crank the engine any more . . . Walmart sells

>>> a gizillion batteries every year that are replaced

>>> in response to that same symptom.

>>>

>>> Some years ago I corresponded with a Cessna 206

>>> floatplane owner in S. America who was wanting to add a

>>> second battery to his ship. We pondered useful volume

>>> to exploit for several exchanges of e-mails. We

>>> finally decided that inside one of the floats was

>>> the best location. The battery could be positioned

>>> right on C.G. and it occupied volume that had

>>> no other purpose.

>>>

>>> After we had corresponded a few times, he agreed

>>> that his REAL worry was for loss of a battery contactor.

>>> He conceded that in the grand scheme of things,

>>> battery maintenance was not a big adder to cost-of-

>>> ownership, his big worry was for loss of battery

>>> contactor that would make the battery unavailable.

>>>

>>> I suggested then than he add a piece of welding cable

>>> to run from downstream side of battery contactor to

>>> the battery box (accessible while standing on a

>>> float). Should preflight testing before tossing

>>> the mooring lines showed that the battery contactor was

>>> "iffy", he could make a manual connection to the

>>> battery (+) terminal with the short jumper.

>>>

>>> He decided that was a much less expensive, lighter

>>> and lower cost plan-C for dealing with a failed

>>> battery contactor. We also discussed simply carrying

>>> a spare contactor and tools . . . but that didn't

>>> cover the potential loss of wiring and/or battery

>>> master switch. So he opted for the jumper-cable

>>> and a pair of pliers.

>>>

>>> The point to ponder is how best to accommodate or

>>> modify a system that is a direct descendant from

>>> systems common to garden tractors: PM alternator,

>>> simple rectifier/regulator and a lead acid battery.

>>>

>>> It seems that the elegant design goal is to craft

>>> a combination of architecture, preventive maintenance\

>>> and operating procedures that accommodates low risk failures

>>> -OR- drives specific failure rates down to insignificance.

>>>

>>> I believe this can be achieved without adding the

>>> weight, cost or complexity of burdening a

>>> garden-tractor-style electrical system with

>>> concepts holy-watered by the FAA and embraced

>>> by Boeing and Airbus.

>>>

>>> This requires a simple but thorough thought

>>> process that goes through the steps of considering

>>> EVERY part of your electrical system from crimped

>>> terminals to alternators and batteries.

>>>

>>> How can this part fail?

>>>

>>> Is failure pre-flight detectable?

>>>

>>> If it fails in flight, how will I know about

>>> it?

>>>

>>> How would in-flight failure affect comfortable

>>> termination of flight?

>>>

>>> What are the lowest cost, lightest weight,

>>> simplest mitigations for the failure?

>>>

>>> Due diligence to Failure Mode Effects Analysis

>>> (FMEA) offers the short-path to the simpler,

>>> lightest weight, lowest cost, lowest risk

>>> (elegant) design easily understood and managed by the

>>> cognizant pilot.

>>>

>>> Bob . . .

>>>

>>> *

>>>

>>> _blank">www.aeroelectric.com

>>> .com" target="_blank">www.buildersbooks.com

>>> ="_blank">www.homebuilthelp.com

>>> ="_blank">www.mypilotstore.com

>>> ank">www.mrrace.com

>>> _blank">http://www.matronics.com/contribution

>>> ist" target="_blank">http://www.matronics.com/Navigator?AeroElectric-List

>>> tp://forums.matronics.com

>>>

>>> *

>>>

>>> *

>>>

>>>

>>> *

>>

>>

>>

>>

>

>

>

>

>

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bob.verwey(at)gmail.com

Guest

|

Posted: Thu Nov 27, 2014 9:50 pm Post subject: alternator / generator Posted: Thu Nov 27, 2014 9:50 pm Post subject: alternator / generator |

|

|

Thanks for a very interesting thread, guys!

Justin, I tend to agree with you on the reliability of the electronic systems.

Where I think the problem comes in, is the inconsistency of the

install, and the integration into the existing system.

Best...

Bob Verwey

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Nov 28, 2014 1:08 pm Post subject: alternator / generator Posted: Fri Nov 28, 2014 1:08 pm Post subject: alternator / generator |

|

|

At 13:32 2014-11-27, you wrote:

| Quote: | An argument can be made both for and against the second battery. I

have considered both and determined that in my case the extra

battery is justified. Your points are nevertheless well taken.

|

Can you share your battery selection and maintenance

program? If you have only one engine driven power source,

then do we presume correctly that you've gathered and

massaged some numbers from which you've developed a

Plan-B . . . a battery only endurance requirement

that will be guarded with periodic measurement?

If you plan to maintain and verify battery(ies)

at some minimum energy content (the general rule

of thumb is 80% of new capacity), is it not

likely that you'll replace batteries before they

become incapable of cranking the engine?

This is the major difference between aviation

and automotive where the battery is often

tasked with two purposes . . . the very

utilitarian purpose of getting the fan

running and the Plan-B purpose of keeping

the panel lit up sans alternator . . . sometimes

for duration of fuel aboard.

This is the core concept for my assertion that

under artfully crafted circumstances, the battery

will become the most robust device in your

suite of engine cranking hardware . . . contrary

to legacy consumer perceptions of battery

dependability.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Fri Nov 28, 2014 4:21 pm Post subject: alternator / generator Posted: Fri Nov 28, 2014 4:21 pm Post subject: alternator / generator |

|

|

At 13:32 2014-11-27, you wrote:

| Quote: | An argument can be made both for and against the second battery. I

have considered both and determined that in my case the extra

battery is justified. Your points are nevertheless well taken.

|

Can you share your battery selection and maintenance

program? If you have only one engine driven power source,

then do we presume correctly that you've gathered and

massaged some numbers from which you've developed a

Plan-B . . . a battery only endurance requirement

that will be guarded with periodic measurement?

If you plan to maintain and verify battery(ies)

at some minimum energy content (the general rule

of thumb is 80% of new capacity), is it not

likely that you'll replace batteries before they

become incapable of cranking the engine?

This is the major difference between aviation

and automotive where the battery is often

tasked with two purposes . . . the very

utilitarian purpose of getting the fan

running and the Plan-B purpose of keeping

the panel lit up sans alternator . . . sometimes

for duration of fuel aboard.

This is the core concept for my assertion that

under artfully crafted circumstances, the battery

will become the most robust device in your

suite of engine cranking hardware . . . contrary

to legacy consumer perceptions of battery

dependability.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Sat Nov 29, 2014 7:30 am Post subject: alternator / generator Posted: Sat Nov 29, 2014 7:30 am Post subject: alternator / generator |

|

|

At 09:52 2014-11-11, you wrote:

| Quote: | The Rotax 914 wiring diagram shows an integrated generator with

external regulator-rectifier and an external alternator with built

in regulator. It looks like the integrated generator is disconnected

from the battery (by relay) when the master is off but the external

alternator remains connected. The text indicates the integrated

generator will run the battery down if not disconnected, but does

not say that for the external alternator. Does this make sense?

|

Sure. The alternators on ALL vehicles are controlled

to a quiescent state when not in use. They present no

load on the battery. Wire per Rotax instructions and

it has a 99.99% probability of functioning as they

intended.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

pestar

Joined: 11 Apr 2007

Posts: 61

Location: Auckland, New Zealand

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|