|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Dec 18, 2023 6:06 am Post subject: OVM-14 MkIII development (update) Posted: Mon Dec 18, 2023 6:06 am Post subject: OVM-14 MkIII development (update) |

|

|

All the proto boards and parts are in.

This is a busy time for festivities and frivolities . . .

having trouble getting back to the bench.

I'm going to try something 'new' for my shop.

The big guns in electronic assembly literally

silk screen solder paste onto component pads

before using a pick-n-place machine to position

parts. The boards are then run through a very

sophisticated oven that preheats and then

flows the solder.

I remember my first experiences with solid state

assembly protocols. 1955 or thereabouts I acquired

my first transistor. A Raytheon CK722. Seems like

they cost about $6 then. All the instructions

for assembling the device into the circuit called

for grabbing the lead with a pair of needle nose

pliers to keep the soldering heat from migrating

up and into the device placing it at risk for

failure.

Nowadays, we can throw whole assemblies into

environments that solder thousands

of joints all at once in mere minutes . . .

I've purchased a hand operated syringe designed

to deposit mosquito poop sized drops of solder

paste onto the pads. I also have a miniature

heat-gun with which I can stick every thing down

in one operation.

I've scheduled some time with my contractor to

modify a workbench in the 'mess making' shop.

We're adding some shelving to support test equipment

over the alternator drive I built up several

years ago for another project. I'm planning to

instrument a mock-up of a complete electrical

system so that we can speak to performance

of system components in terms of measured values.

Watch this space.

Bob . . .

////

(o o)

===========o00o=(_)=o00o=========

< Go ahead, make my day . . . >

< show me where I'm wrong. >

=================================

In the interest of creative evolution

of the-best-we-know-how-to-do based

on physics and good practice.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

bob.verwey(at)gmail.com

Guest

|

Posted: Mon Dec 18, 2023 7:22 am Post subject: OVM-14 MkIII development (update) Posted: Mon Dec 18, 2023 7:22 am Post subject: OVM-14 MkIII development (update) |

|

|

Bob my optical focus is more and more a challenge when dealing with more and more minutuarized components!

On Mon, 18 Dec 2023, 16:09 Robert L. Nuckolls, III, <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | All the proto boards and parts are in.

This is a busy time for festivities and frivolities . . .

having trouble getting back to the bench.

I'm going to try something 'new' for my shop.

The big guns in electronic assembly literally

silk screen solder paste onto component pads

before using a pick-n-place machine to position

parts. The boards are then run through a very

sophisticated oven that preheats and then

flows the solder.

I remember my first experiences with solid state

assembly protocols. 1955 or thereabouts I acquired

my first transistor. A Raytheon CK722. Seems like

they cost about $6 then. All the instructions

for assembling the device into the circuit called

for grabbing the lead with a pair of needle nose

pliers to keep the soldering heat from migrating

up and into the device placing it at risk for

failure.

Nowadays, we can throw whole assemblies into

environments that solder thousands

of joints all at once in mere minutes . . .

I've purchased a hand operated syringe designed

to deposit mosquito poop sized drops of solder

paste onto the pads. I also have a miniature

heat-gun with which I can stick every thing down

in one operation.

I've scheduled some time with my contractor to

modify a workbench in the 'mess making' shop.

We're adding some shelving to support test equipment

over the alternator drive I built up several

years ago for another project. I'm planning to

instrument a mock-up of a complete electrical

system so that we can speak to performance

of system components in terms of measured values.

Watch this space.

Bob . . .

////

(o o)

===========o00o=(_)=o00o=========

< Go ahead, make my day . . .  >

< show me where I'm wrong.     >

=================================

Â

In the interest of creative evolution

of the-best-we-know-how-to-do based

on physics and good practice.

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

rv8iator

Joined: 11 Apr 2006

Posts: 144

Location: Newberg, OR

|

Posted: Mon Dec 18, 2023 7:28 am Post subject: OVM-14 MkIII development (update) Posted: Mon Dec 18, 2023 7:28 am Post subject: OVM-14 MkIII development (update) |

|

|

Bob et al...

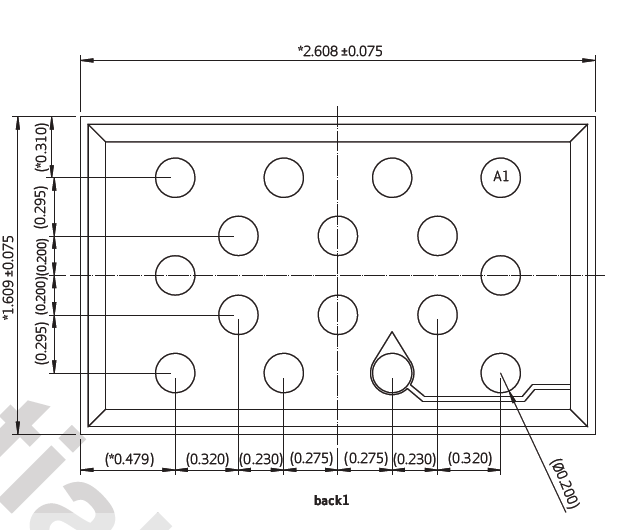

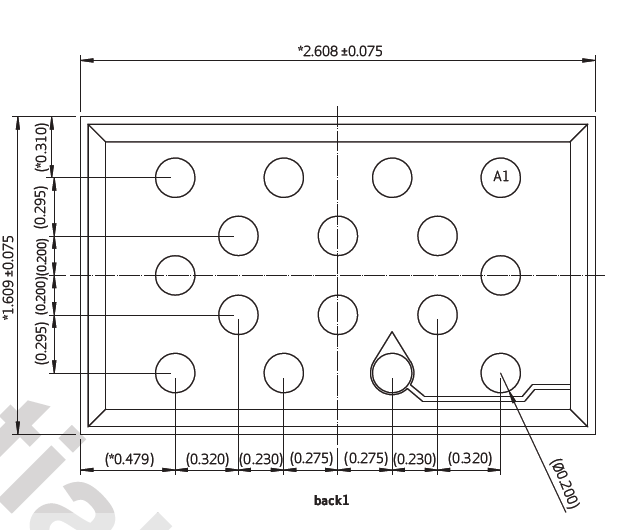

This is a BGA component (Dims in mm) that is soldered to a slightly larger motherboard. All our fabs are pick and place. Most boards 6 layers with .010 in traces. We get some components that are manufactured in millimeters and our design software (Altium) likes inch grids... The conversion is four significant digits so it's only a matter of making sure you remember what units you are working in...

I only bring this up as boards and fab have really become quite inexpensive. I do 5 piece and 10 piece board proto lots.

Fun stuff!

.Chris

Another RV

[img]cid:ii_lqb28zcx0[/img]

On Mon, Dec 18, 2023 at 6:09â¯AM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | All the proto boards and parts are in.

This is a busy time for festivities and frivolities . . .

having trouble getting back to the bench.

I'm going to try something 'new' for my shop.

The big guns in electronic assembly literally

silk screen solder paste onto component pads

before using a pick-n-place machine to position

parts. The boards are then run through a very

sophisticated oven that preheats and then

flows the solder.

I remember my first experiences with solid state

assembly protocols. 1955 or thereabouts I acquired

my first transistor. A Raytheon CK722. Seems like

they cost about $6 then. All the instructions

for assembling the device into the circuit called

for grabbing the lead with a pair of needle nose

pliers to keep the soldering heat from migrating

up and into the device placing it at risk for

failure.

Nowadays, we can throw whole assemblies into

environments that solder thousands

of joints all at once in mere minutes . . .

I've purchased a hand operated syringe designed

to deposit mosquito poop sized drops of solder

paste onto the pads. I also have a miniature

heat-gun with which I can stick every thing down

in one operation.

I've scheduled some time with my contractor to

modify a workbench in the 'mess making' shop.

We're adding some shelving to support test equipment

over the alternator drive I built up several

years ago for another project. I'm planning to

instrument a mock-up of a complete electrical

system so that we can speak to performance

of system components in terms of measured values.

Watch this space.

Bob . . .

////

(o o)

===========o00o=(_)=o00o=========

< Go ahead, make my day . . .  >

< show me where I'm wrong.     >

=================================

Â

In the interest of creative evolution

of the-best-we-know-how-to-do based

on physics and good practice.

|

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

40.03 KB |

| Viewed: |

2330 Time(s) |

|

_________________

C. Stone (RV8iator) |

|

| Back to top |

|

|

Ceengland

Joined: 11 Oct 2020

Posts: 381

Location: MS

|

Posted: Mon Dec 18, 2023 8:38 am Post subject: OVM-14 MkIII development (update) Posted: Mon Dec 18, 2023 8:38 am Post subject: OVM-14 MkIII development (update) |

|

|

On Mon, Dec 18, 2023 at 8:09â¯AM Robert L. Nuckolls, III <nuckolls.bob(at)aeroelectric.com (nuckolls.bob(at)aeroelectric.com)> wrote:

| Quote: | All the proto boards and parts are in.

This is a busy time for festivities and frivolities . . .

having trouble getting back to the bench.

I'm going to try something 'new' for my shop.

The big guns in electronic assembly literally

silk screen solder paste onto component pads

before using a pick-n-place machine to position

parts. The boards are then run through a very

sophisticated oven that preheats and then

flows the solder.

snip

Nowadays, we can throw whole assemblies into

environments that solder thousands

of joints all at once in mere minutes . . .

I've purchased a hand operated syringe designed

to deposit mosquito poop sized drops of solder

paste onto the pads. I also have a miniature

heat-gun with which I can stick every thing down

in one operation.

snip

|

Â

| Quote: | of system components in terms of measured values.

Watch this space.

Bob . . .

|

A friend of mine designed and has been making the control head/monitors for E-Mag ignition systems for many years, using surface mount components.  He copied what hobbyists were doing; they used a particular brand of 'toaster oven' that has accurate temperature control. So if you have an E-Mag control head, it came from an 'easy bake oven'.

CharlieÂ

Virus-free.www.avast.com[url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url] Virus-free.www.avast.com[url=#DAB4FAD8-2DD7-40BB-A1B8-4E2AA1F9FDF2][/url]

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Charlie |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Dec 18, 2023 10:04 am Post subject: OVM-14 MkIII development (update) Posted: Mon Dec 18, 2023 10:04 am Post subject: OVM-14 MkIII development (update) |

|

|

At 09:21 AM 12/18/2023, you wrote:

| Quote: | | Bob my optical focus is more and more a challenge when dealing with more and more minutuarized components! |

Yeah . . . While at Beech, I purchased a binocular

microscope with a camera port. Invaluable tool for

chasing down root cause for sticking relays, broken

shafts, poor craftsmanship, etc. Now it's handy

for working etched circuit boards! I don't use

anything smaller than 1206 components but the

next gen OVM got laid out really tight so the

board will STILL fit under 1/2" heat shrink.

I'm thinking of seeing if some of my contractor's

grand kids would be interested in learning to

assemble things like this. Thought it would

be wise to pursue an upgrade to our shade-tree

processes. The poop-n-blast technique seems

like a logical 'upgrade'.

Bob . . .

////

(o o)

===========o00o=(_)=o00o=========

< Go ahead, make my day . . . >

< show me where I'm wrong. >

=================================

In the interest of creative evolution

of the-best-we-know-how-to-do based

on physics and good practice.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Dec 18, 2023 11:21 am Post subject: OVM-14 MkIII development (update) Posted: Mon Dec 18, 2023 11:21 am Post subject: OVM-14 MkIII development (update) |

|

|

| Quote: | A friend of mine designed and has been making the control

head/monitors for E-Mag ignition systems for many years, using

surface mount components. He copied what hobbyists were doing;

they used a particular brand of 'toaster oven' that has

accurate temperature control. So if you have an E-Mag

control head, it came from an 'easy bake oven'.

|

Yeah, I've been aware of a constellation of

reflow tools for DIY assembly for a number

of years. About 10 years ago, I bought an

early version of this thing.

Made it work okay . . . but it took up a lot

of room on the bench and was a tool I used

for perhaps an 2 hours per month. It was

just not very practical for my products

with tiny boards. Still had some thru-hole

products that were not oven-friendly.

My little hot-air rework station seemed

to be a better fit for my mix of repair/

manufacturing tasks. Didn't take up much

room. Virtually zero 'set up' . . . one

could visually adjust technique on the

fly. Was a whole lot cheaper too!

I'm reminded of the exciting day that

we purchased a wave soldering machine

at Electro-Mech. We kept it for less

than a year. There was a lot of 'back-office'

work to store up enough boards to justify

firing the thing up for a run . . . that

might take less than an hour to solder a

months worth of production.

The thing proved to be a bottle-neck in

work flow for an operation that produced

a relatively small quantities of dozens of

products that were needed at the customer

in a smooth JIT flow.

Our assembly line of skilled craftspersons

proved more practical for managing

work-flow.

Bob . . .

////

(o o)

===========o00o=(_)=o00o=========

< Go ahead, make my day . . . >

< show me where I'm wrong. >

=================================

In the interest of creative evolution

of the-best-we-know-how-to-do based

on physics and good practice.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

109.69 KB |

| Viewed: |

2314 Time(s) |

|

|

|

| Back to top |

|

|

Eric Page

Joined: 15 Feb 2017

Posts: 243

|

Posted: Mon Dec 18, 2023 3:07 pm Post subject: Re: OVM-14 MkIII development (update) Posted: Mon Dec 18, 2023 3:07 pm Post subject: Re: OVM-14 MkIII development (update) |

|

|

Those Chinese T-962 reflow ovens are well known in the hobbyist community for having hot and cold spots, sometimes poor internal wiring, and for not following IPC profiles very well. There's an open-source project out there for a replacement controller that makes them work better.

I use an old toaster oven with a failed thermostat that makes it run full blast regardless of setting (I ate out the day that happened!). I picked up a cheap industrial ramp/soak PID controller to run it. The only modification necessary was to cover the inside of the window in its door with aluminum foil to minimize radiated heat loss. It now works like a charm and cost only a few dollars.

If you want to build a toaster oven reflow setup, look for an oven with quartz heating elements; they're reputed to allow faster temperature ramps, making it easier to follow the right profile.

-Eric

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Mon Dec 18, 2023 7:33 pm Post subject: OVM-14 MkIII development (update) Posted: Mon Dec 18, 2023 7:33 pm Post subject: OVM-14 MkIII development (update) |

|

|

At 05:07 PM 12/18/2023, you wrote:

| Quote: | --> AeroElectric-List message posted by: "Eric Page" <edpav8r(at)yahoo.com>

Those Chinese T-962 reflow ovens are well known in the hobbyist community for having hot and cold spots, sometimes poor internal wiring, and for not following IPC profiles ( https://www.ipc.org/TOC/IPC-7801.pdf) very well. There's an open-source project out there for a replacement controller that makes them work better.

I use an old toaster oven with a failed thermostat that makes it run full blast regardless of setting (I ate out the day that happened!). I picked up a cheap industrial ramp/soak PID controller to run it. The only modification necessary was to cover the inside of the window in its door with aluminum foil to minimize radiated heat loss. It now works like a charm and cost only a few dollars.

If you want to build a toaster oven reflow setup, look for an oven with quartz heating elements; they're reputed to allow faster temperature ramps, making it easier to follow the right profile.

|

Good info sir. Thank you!

I think the T-962 has evolved to mitigate some

of its shortcomings. The one I bought needed

a number of mods right out of the box . . but

it ultimately seemed adequate . . . jut more

than I needed. Kinda like doing in ants

with a sledgehammer!

Bob . . .

////

(o o)

===========o00o=(_)=o00o=========

< Go ahead, make my day . . . >

< show me where I'm wrong. >

=================================

In the interest of creative evolution

of the-best-we-know-how-to-do based

on physics and good practice.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|