|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

Area-51

Joined: 03 May 2021

Posts: 373

|

Posted: Sat Dec 03, 2022 6:49 am Post subject: The Obsidian File - Mono Undercarriage Posted: Sat Dec 03, 2022 6:49 am Post subject: The Obsidian File - Mono Undercarriage |

|

|

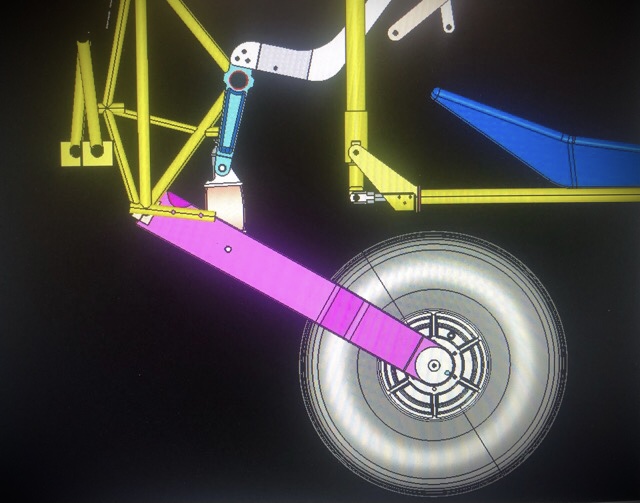

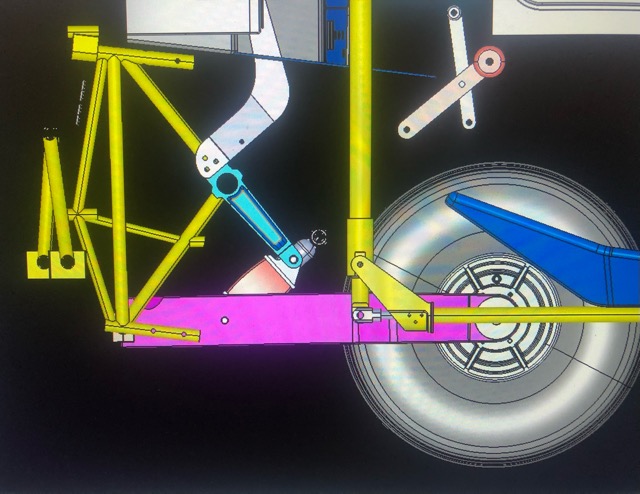

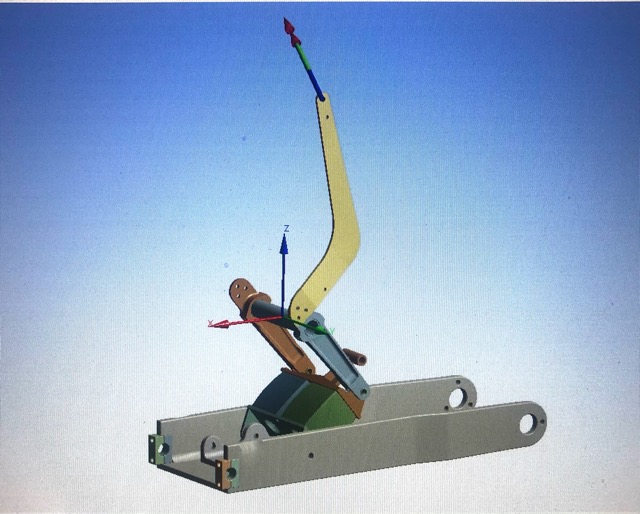

With the 3D aero model now complete its onto a new chapter as mechanical and ancillaries come into the fore; and fruit has arrived straight off the get go.

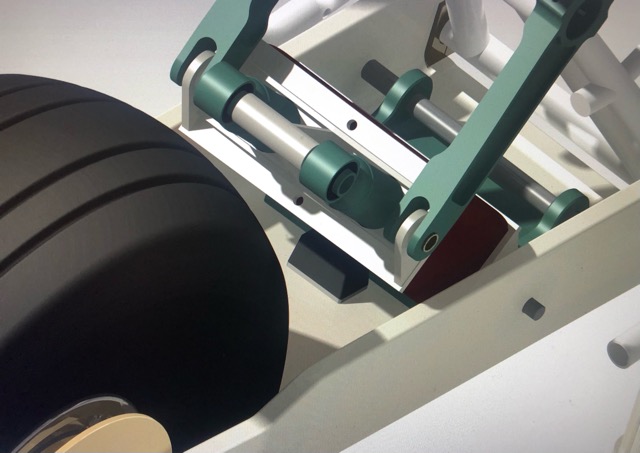

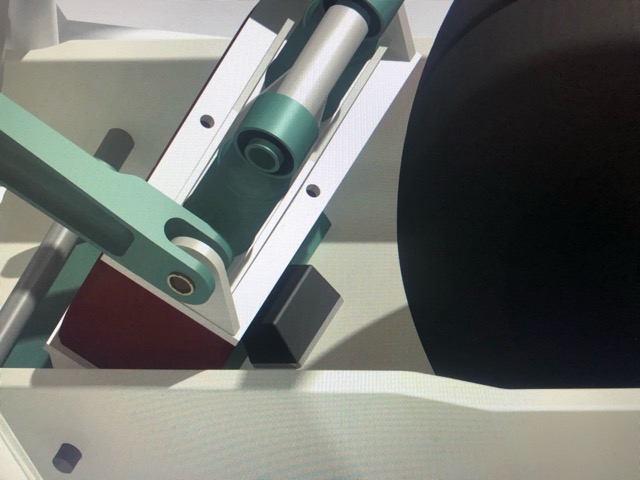

After reading and hearing about so many issues regarding the mono retract the first thing that has been focused upon is the undercarriage. Having the model available now provides the ability to try things out and get answers almost instantly. So that's exactly what happened as soon as the remaining components of the assembly were drafted and imported into the picture today.

The first goto was undercarriage action; why does it jam closed on some aircraft? Why is it so difficult to retract when throwing that final bit of the lever forward? It was interesting what showed up! An initial earlier solution drafted last year was quickly thrown in the bin but it was this study that revealed where the issue actually now resided.

Having the 3D CAD components assembled allowed a study of the geometry of the retractable assembly, and sure enough it was so very possible to jam the undercarriage in the retracted position; and was remarkably easy to affect; literally just a mm or two beyond the gate stop on the console did it and the wheel was stuck fast in the tunnel void.

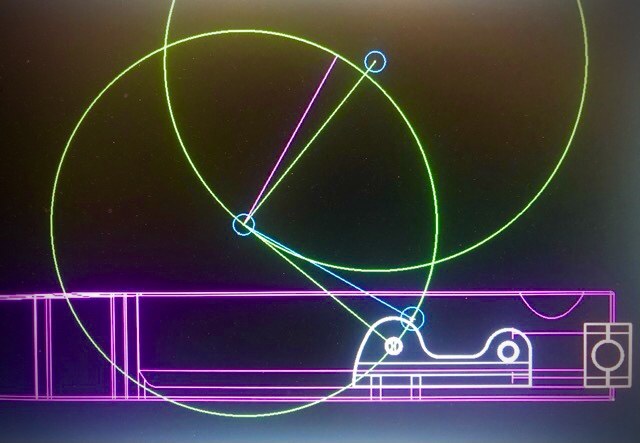

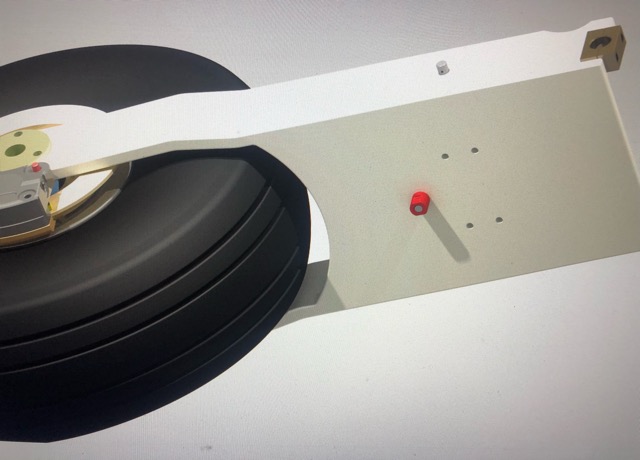

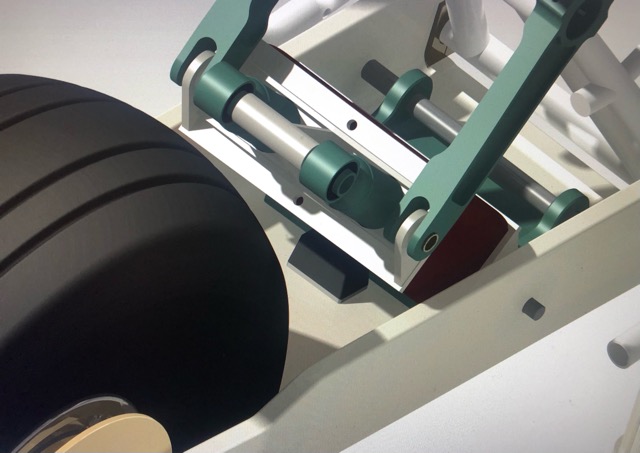

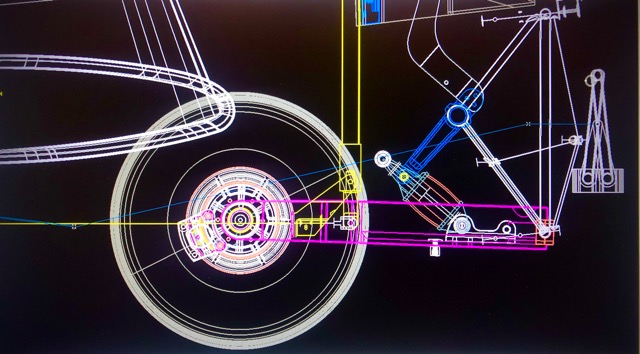

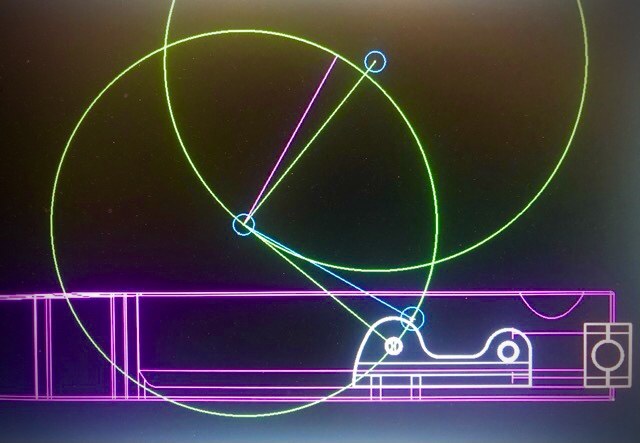

It was instantly apparent that the only way this could geometrically be possible is if one of the mechanical arms has moved passed a point to rest within a 90deg quadrant. So that's where the focus went to and thats what was quickly flushed out... the rubber block assembly had crossed over and was resting at 80deg to the swing of its upstream link. And there it was, with the only thing preventing jamming in situ now being the weight of the main wheel overcoming the tension of the bungee spring... Its the very same reason causing that last bit of retract throw on the cockpit lever being difficult; and perhaps the very same reason some owners simply tighten up the bungee spring to get things to park up. (The attached geometry image shows the factory positioning at the blue circles, the magenta line being the 90deg quadrant marker relative to pin LG04's position, the blue line represents the rubber block assembly, and the relative green line LG08).

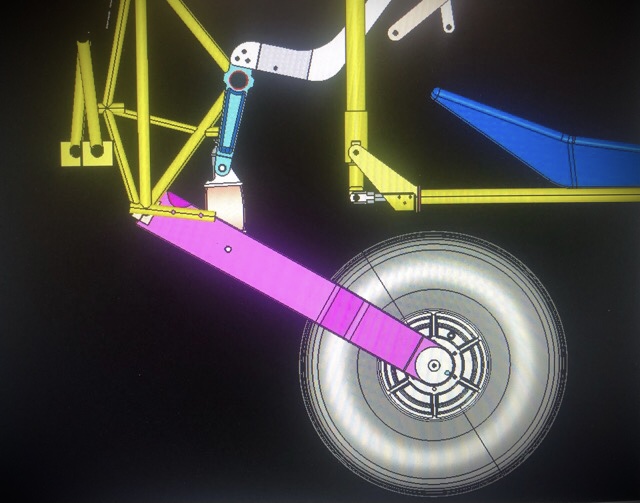

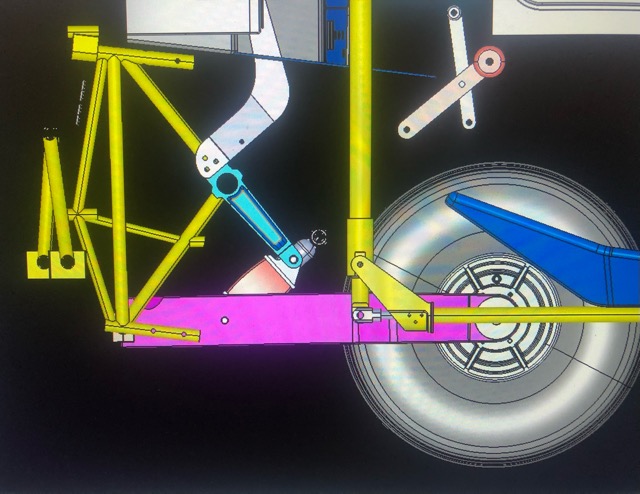

So gee what to do? ?? Well what if things get realigned to their respective 90deg quadrant? The numbers indicate nothing will alter at the cockpit lever position... worth a go; what's required? Rotate a single pivot point on its radius 10deg and revision of LG02A... So that's what got drafted out and presto, problem instantly gone away to the graveyard of great ideas... Amazing!!! Took all of five minutes to solve on the 2D and another 10 to draft up a new 3D functional component and check for clashing and binding.

With pin LG04's position at LG02A now rotated 10deg on the spring blocks arc it is now geometrically impossible to jam the undercarriage; even if the main wheel somehow finds its way up through the tunnel ceiling to the instrument panel facia; which it now can do if the lever is moved beyond its gated travel, which has remained unchanged.

So that's it, MOD-XX... Done!

Fitting of LG02A-XX and reboring of LG02 for LG04's amended position, being 150mm horizontal and 7mm vertical from the datum centre bore of LG03.

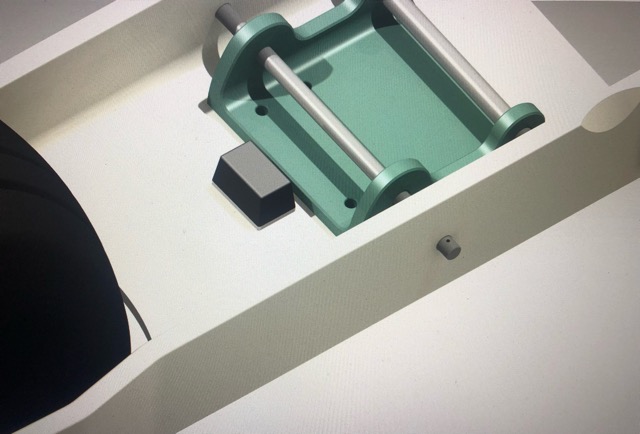

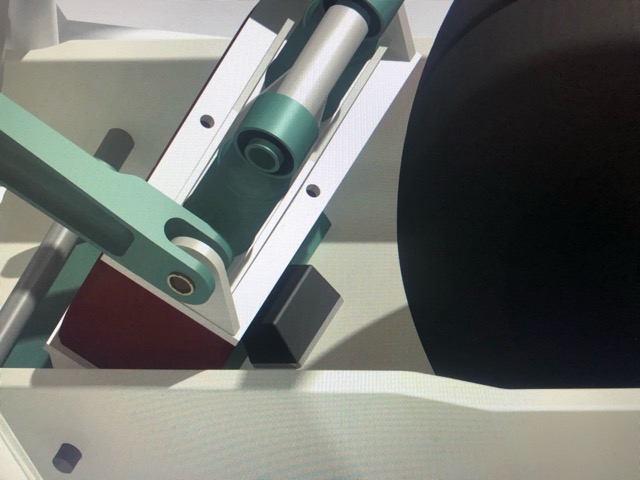

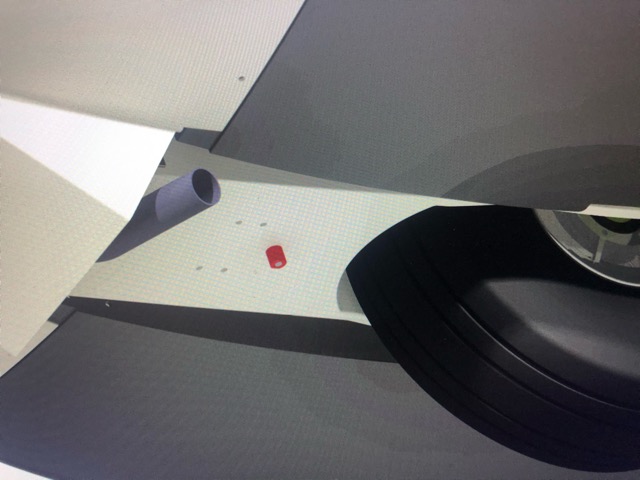

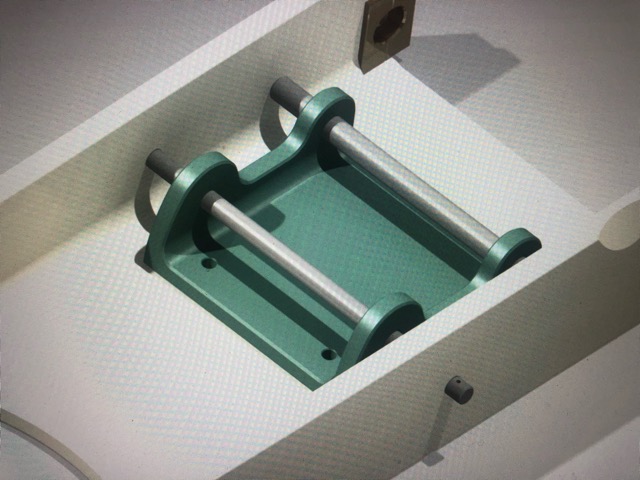

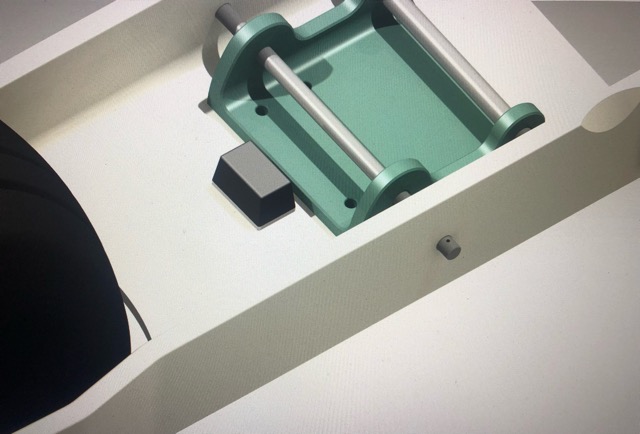

The other attached images show the difference between LG02A and LG02A-XX; the position of the bungee pin on LG02-XX has also been raised a few mm for better operational clearance... LG08 also received a slight mod to become one manufactured component instead of two.

So can somebody please explain what the bungee spring actually does??? I cannot find or identify a practical mechanical reason for it at all other than to overcome the existing geometry error; unless this perceived error is intentional?

Thanks for reading everything; well done!

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

80.27 KB |

| Viewed: |

1966 Time(s) |

|

| Description: |

|

| Filesize: |

89.9 KB |

| Viewed: |

1966 Time(s) |

|

| Description: |

|

| Filesize: |

94.77 KB |

| Viewed: |

1966 Time(s) |

|

| Description: |

|

| Filesize: |

83.09 KB |

| Viewed: |

1966 Time(s) |

|

| Description: |

|

| Filesize: |

82.53 KB |

| Viewed: |

1966 Time(s) |

|

Last edited by Area-51 on Sat Dec 03, 2022 12:25 pm; edited 3 times in total |

|

| Back to top |

|

|

peterz(at)zutrasoft.com

Guest

|

Posted: Sat Dec 03, 2022 8:45 am Post subject: The Obsidian File - Mono Undercarriage Posted: Sat Dec 03, 2022 8:45 am Post subject: The Obsidian File - Mono Undercarriage |

|

|

Fwiw, my experience:

1- difficulty in getting the gear into to and out of the up-gate (regardless of bungy tension) was due to the flap rod adjustment being too short, causing the flaps to top-out, restricting the gear up travel.

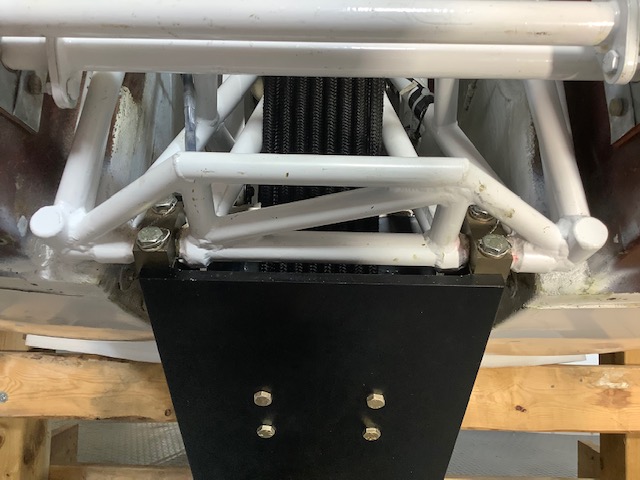

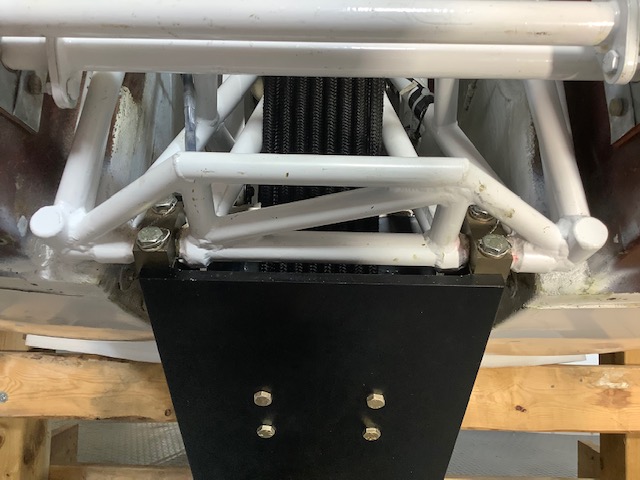

2- general binding of the swing-arm was due to a bent gear/engine frame pivot tube. Bent due to having been side loaded when the gear was in the down position, an angle where that tube is totally unbraced/supported. I suspect many frames in the field are bent. The builder of my bird had actually shimmed the arm bushing to accommodate and reduce the binding (band aid solution). When repairing my frame, i added a truss to the frame at the correct angle to support the tube and prevent any future bending.

3- the bungee is simply to assist the pilot in raising the gear. I tensioned mine such that it pulls the gear up about 60% when doing the gear swing test. I find that with this tension my gear takes minimal effort over its entire swing range in flight.

Cheers,

PeteZ

| Quote: | On Dec 3, 2022, at 9:55 AM, Area-51 <goldsteinindustrial(at)gmail.com> wrote:

With the 3D aero model now complete its onto a new chapter as mechanical and ancillaries come into the fore; and fruit has arrived straight off the get go.

After reading and hearing about so many issues regarding the mono retract the first thing that has been focused upon is the undercarriage. Having the model available now provides the ability to try things out and get answers almost instantly. So that's exactly what happened as soon as the remaining components of the assembly were drafted and imported into the picture today.

The first goto was undercarriage action; why does it jam closed on some aircraft? Why is it so difficult to retract when throwing that final bit of the lever forward? It was interesting what showed up! An initial earlier solution drafted last year was quickly thrown in the bin but it was this study that revealed where the issue actually now resided.

Having the 3D CAD components assembled allowed a study of the geometry of the retractable assembly, and sure enough it was so very possible to jam the undercarriage in the retracted position; and was remarkably easy to affect; literally just a mm or two beyond the gate stop on the console did it and the wheel was stuck fast in the tunnel void.

It was instantly apparent that the only way this could geometrically be possible is if one of the mechanical arms has moved passed a point to rest within a 90deg quadrant. So that's where the focus went to and thats what was quickly flushed out... the rubber block assembly had crossed over and was resting at 80deg to the swing of its upstream link. And there it was, with the only thing preventing jamming in situ now being the weight of the main wheel overcoming the tension of the bungee spring... Its the very same reason causing that last bit of retract throw on the cockpit lever being difficult; and perhaps the very same reason some owners simply tighten up the bungee spring to get things to park up. (The attached geometry image shows the factory positioning at the blue circles, the magenta line being the 90deg quadrant marker relative to pin LG04's position, the blue line represents the rubber block assembly).

So gee what to do? ?? Well what if things get realigned to their respective 90deg quadrant? worth a go; what's required? Rotate a single pivot point 10deg and revision of LG02A... So that's what got drafted out and presto, problem instantly gone away to the graveyard of great ideas... Amazing!!! Took all of five minutes to solve on the 2D and another 10 to draft up a new 3D functional component and check for clashing and binding.

With pin LG04's position at LG02A now rotated 10deg on the spring blocks arc it is now geometrically impossible to jam the undercarriage; even if the main wheel somehow finds its way up through the tunnel ceiling to the instrument panel facia; which it now can do if the lever is moved beyond its gated travel.

So that's it, MOD-XX... Done!

Fitting of LG02A-XX and reboring of LG02 for LG04's amended position, being 150mm horizontal and 7mm vertical from the datum centre bore of LG03.

The other attached images show the difference between LG02A and LG02A-XX; the position of the bungee pin on LG02-XX has also been raised a few mm for better operational clearance.

So can somebody please explain what the bungee spring actually does??? I cannot find or identify a practical mechanical reason for it at all other than to overcome the existing geometry error; unless this perceived error is intentional?

Thanks for reading everything; well done!

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=509435#509435

Attachments:

http://forums.matronics.com//files/0c2811c4_5687_479e_8d89_ed360c7f4c9c_437.jpeg

http://forums.matronics.com//files/5c1a69af_790e_4a51_a3bd_8506e15c35f6_343.jpeg

http://forums.matronics.com//files/e8371182_c043_4319_a5aa_c216cd42e8bb_157.jpeg

http://forums.matronics.com//files/f6e8ca6f_6a3a_43da_8d31_fb5ae6e8e277_189.jpeg

http://forums.matronics.com//files/0ef69eca_b797_45ac_828c_7cdc5f70dafb_189.jpeg

====================================

|

====================================

====================================

====================================

====================================

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

74.3 KB |

| Viewed: |

1961 Time(s) |

|

| Description: |

|

| Filesize: |

110.53 KB |

| Viewed: |

1961 Time(s) |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 373

|

Posted: Sat Dec 03, 2022 7:06 pm Post subject: Re: The Obsidian File - Mono Undercarriage Posted: Sat Dec 03, 2022 7:06 pm Post subject: Re: The Obsidian File - Mono Undercarriage |

|

|

Nice solution Peter; what gauge tubing has been used there?

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 373

|

Posted: Sat Dec 03, 2022 9:26 pm Post subject: Re: The Obsidian File - Mono Undercarriage Posted: Sat Dec 03, 2022 9:26 pm Post subject: Re: The Obsidian File - Mono Undercarriage |

|

|

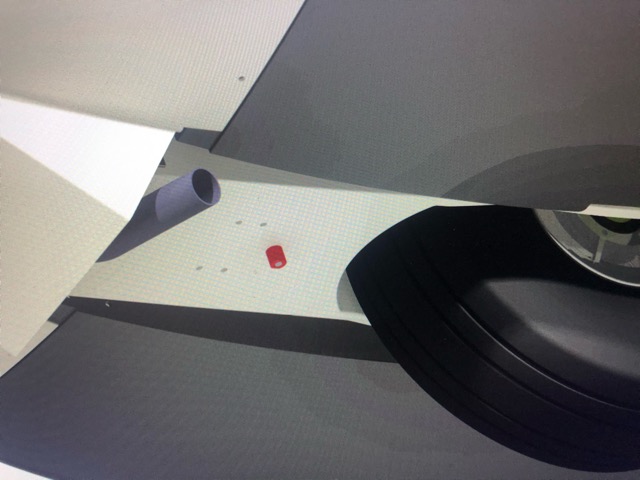

Some further thoughts today upon this.

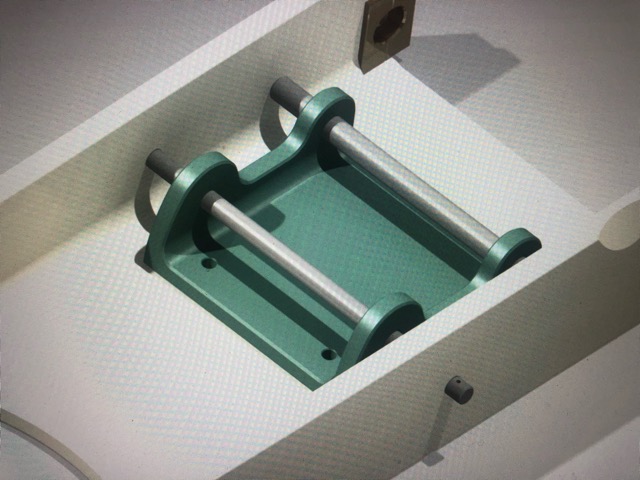

With a focus toward keeping things as simple as possible a fast solution to more easily employ was brought in after a discussion with another Europian... The latest mod employs a buffer stop mounted on LG02 to prevent the undercarriage raising too far up into the tunnel and the rubber block assembly reaching the geometric locking position. The height of the buffer can be altered by placing washers under its base thus adjusting the parking position of LG02.

The nut fixing the buffer to LG02 has been given the function of a jacking pin for security and safety purposes.

Some photos included.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

61.4 KB |

| Viewed: |

1933 Time(s) |

|

| Description: |

|

| Filesize: |

55.86 KB |

| Viewed: |

1933 Time(s) |

|

| Description: |

|

| Filesize: |

69.71 KB |

| Viewed: |

1933 Time(s) |

|

| Description: |

|

| Filesize: |

66.99 KB |

| Viewed: |

1933 Time(s) |

|

| Description: |

|

| Filesize: |

60.62 KB |

| Viewed: |

1933 Time(s) |

|

|

|

| Back to top |

|

|

Dave Disney

Joined: 16 Aug 2010

Posts: 54

Location: Weston-Super-Mare

|

Posted: Sun Dec 04, 2022 2:51 am Post subject: Re: The Obsidian File - Mono Undercarriage Posted: Sun Dec 04, 2022 2:51 am Post subject: Re: The Obsidian File - Mono Undercarriage |

|

|

This is an interesting subject.

The question is asked what the bungee actually does. I replaced my bungee a couple of years ago and did some retractions without it (aircraft jacked in the hangar so no aerodynamic assistance). It was bloody hard work to retract without the bungee. When I installed the new bungee it had 1 extra loop and was tensioned a lot more than the one I removed. The gear is now really easy to operate both in the air and in the hangar!

I'm not quite sure I agree with your overcentre analysis. I am one of the few who have done a wheel up landing (not because I forgot, but don't ask how it happened). After the landing the gear was really easy to lower despite the fact that it had gone right up into the tunnel with the wheel contacting the throttle lever and the brake caliper severing a rudder cable. With the wheel going this far up, wouldn't your overcentre case be realised?

On another topic, I really like your 3D modelling. I have produced a Solidworks 3D model for the fuselage frame by taking measurements and reverse engineering it. I'm doing this for a new conventional gear design I'm working on. I would love to compare my model with yours, what software are you using for your modelling and how are you going about it?

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

peterz(at)zutrasoft.com

Guest

|

|

| Back to top |

|

|

peterz(at)zutrasoft.com

Guest

|

Posted: Sun Dec 04, 2022 4:25 am Post subject: The Obsidian File - Mono Undercarriage Posted: Sun Dec 04, 2022 4:25 am Post subject: The Obsidian File - Mono Undercarriage |

|

|

5/8x0.035”

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 373

|

Posted: Sun Dec 04, 2022 7:11 am Post subject: Re: The Obsidian File - Mono Undercarriage Posted: Sun Dec 04, 2022 7:11 am Post subject: Re: The Obsidian File - Mono Undercarriage |

|

|

Thanks, much appreciated... can i have your permission to copy your mod into the mix?

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 373

|

Posted: Sun Dec 04, 2022 7:20 am Post subject: Re: The Obsidian File - Mono Undercarriage Posted: Sun Dec 04, 2022 7:20 am Post subject: Re: The Obsidian File - Mono Undercarriage |

|

|

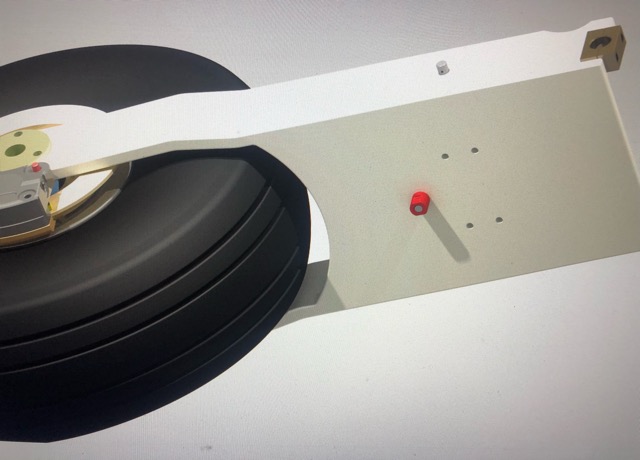

Today repositioning of the brake caliper was given a quick review after string lining in the rudder cables; and it revealed that John had indeed flipped the classic tailwheel block upside down to gain better cable alignment... a moment force study was also commenced on yesterday's mod to LG02A to determine the affect at the operator handle end of the situation; will have to run the same test again on the current setup to compare.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

85.01 KB |

| Viewed: |

1838 Time(s) |

|

| Description: |

|

| Filesize: |

65.8 KB |

| Viewed: |

1838 Time(s) |

|

Last edited by Area-51 on Sun Dec 04, 2022 7:43 am; edited 1 time in total |

|

| Back to top |

|

|

peterz(at)zutrasoft.com

Guest

|

|

| Back to top |

|

|

Jon Smith

Joined: 12 Dec 2021

Posts: 2

|

Posted: Sun Dec 04, 2022 12:14 pm Post subject: Re: The Obsidian File - Mono Undercarriage Posted: Sun Dec 04, 2022 12:14 pm Post subject: Re: The Obsidian File - Mono Undercarriage |

|

|

My thoughts about altering the retraction geometry; If I’ve got it right, your proposal is to move the bottom pivot (the LG8 pin) forward a bit, albeit on an arc. My uneducated opinion is that may well reduce the amount of over-centre of the down-lock geometry to a critically small amount that could lead to the undercarriage unlocking and collapsing. The amount of over-centre is quite small anyway; the centre pivot should be 1/16” to 1/8” forward of a line between the top & bottom pivots. If it’s less than 1/16”the over-centre lock will be dangerously weak and at risk of unlocking whereas if it’s any more than 1/8” too much load will be put on the frame, running the risk of frame damage. IMHO the original design was developed for very good reasons and does not need messing around with! If it’s built correctly and if it’s then maintained correctly it should not fail.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

_________________

G-TERN |

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 373

|

Posted: Sun Dec 04, 2022 3:52 pm Post subject: Re: The Obsidian File - Mono Undercarriage Posted: Sun Dec 04, 2022 3:52 pm Post subject: Re: The Obsidian File - Mono Undercarriage |

|

|

Jon, thanks for your thoughts there however needs correcting..

Position of LG08 components are not altered; the over center locking affect on extension is actually marginally improved.

Pin LG04 is moved slightly rearward and down upon its arc, relative to the opposite pivot point at LG08. This keeps the rubber spring block assembly outside of a 90deg arc from LG08 when retracted. If things here cross over less than 90deg they can jam in the retracted position if the bungee is too tight.

Apart for preventing a possible lock up in the retracted position the operation of the landing gear is otherwise unchanged. Moving the position of LG04 adds mechanical advantage at the final end of retraction; which the bungee currently provides.

The addition of a sacrificial $1.75 buffer prevents retracting of the undercarriage too far into a possible lock up position. The above repositioning of pin LG04 is helpful but not required... with washer and nylock nut the $1.75 buffer is now probably $2.30. The shortened and filed tube nut for the jacking pin probably brings things to $2.50 but i could be wrong...

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 373

|

Posted: Sun Dec 04, 2022 10:54 pm Post subject: Re: The Obsidian File - Mono Undercarriage Posted: Sun Dec 04, 2022 10:54 pm Post subject: Re: The Obsidian File - Mono Undercarriage |

|

|

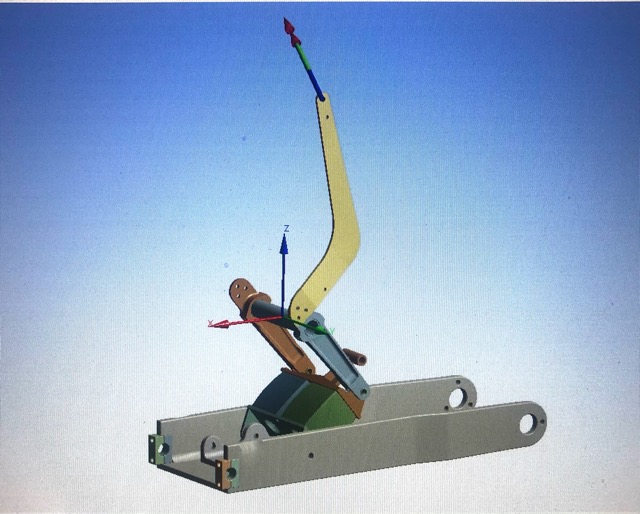

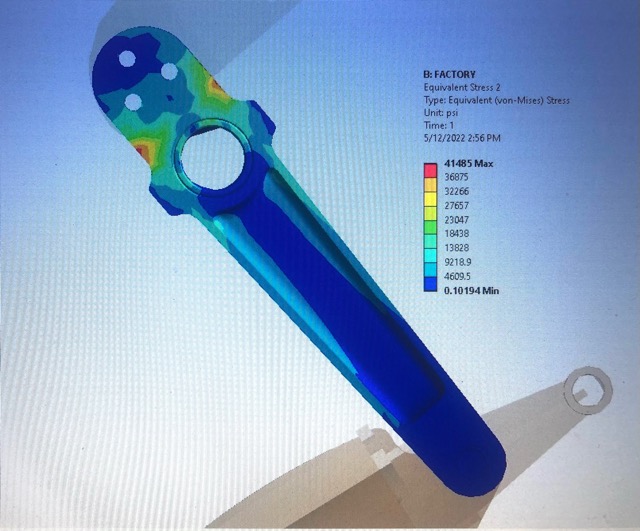

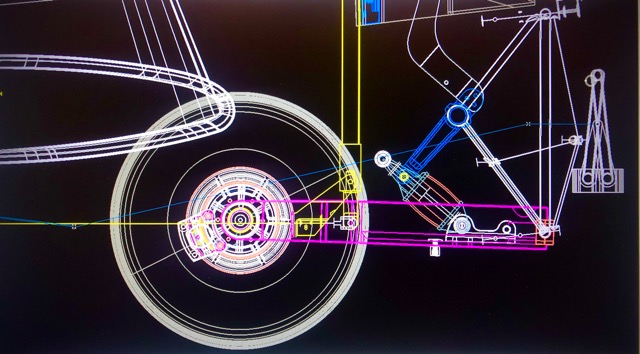

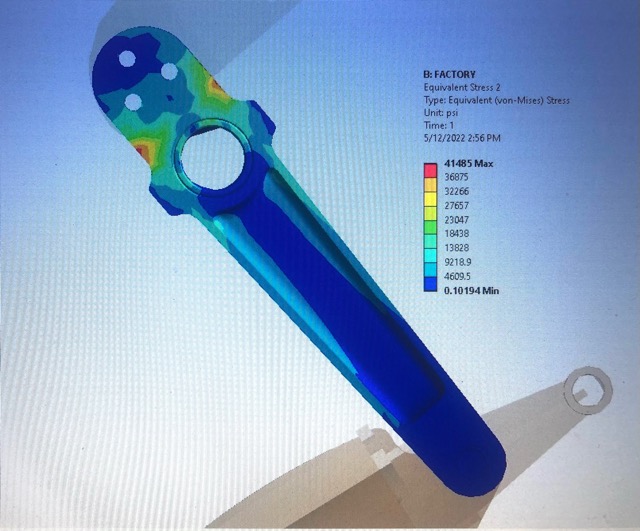

Today the numbers on mod-xx were run through the trap. Short story 50% reduction in component stress and force required at the operator end.

Both factory and mod-xx had the same parameters applied along with a gravity to factor in the torque of the swing arm's mass. LG12 undercarriage lever has been modelled using 4.0mm 1020 sheet steel. LG02 and LG08 have been supplemented with 6061-T6; the rubber spring block has also been supplemented with 6061-T6 for simplification of the model and approximation of mass factor.

At close out of the undercarriage retraction (the final point of retraction) the factory setup delivered a 30200 Nm moment from LG08's axis to the operator handle while mod-xx delivered 13600 Nm.

Force required in the X direction (forward moving) at the operator handle for the factory setup was 700 N while mod-xx required 320 N.

Tension force required at the bungee to reach zero mass balance of the LG02 undercarriage arm assembly upon its swing axis was 860 N.

The assembly model received a vertical force of 100 N at the main wheel axle line along with a gravity factor of 1.. bungee tension was not added to either test model.

Altering the position of LG04 10deg upon its radius centroid to its opposite axis at LG08 was causal to the change in measured affects.

This concludes this part of this Obsidian File chapter to further discussion.

Images included for the technically minded.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

| Description: |

|

| Filesize: |

92.96 KB |

| Viewed: |

1787 Time(s) |

|

| Description: |

|

| Filesize: |

94.78 KB |

| Viewed: |

1787 Time(s) |

|

| Description: |

|

| Filesize: |

106.36 KB |

| Viewed: |

1787 Time(s) |

|

| Description: |

|

| Filesize: |

135.03 KB |

| Viewed: |

1787 Time(s) |

|

| Description: |

|

| Filesize: |

137.93 KB |

| Viewed: |

1787 Time(s) |

|

|

|

| Back to top |

|

|

Duncan McFadyean

Joined: 18 Jan 2011

Posts: 218

|

Posted: Mon Dec 05, 2022 2:22 am Post subject: The Obsidian File - Mono Undercarriage Posted: Mon Dec 05, 2022 2:22 am Post subject: The Obsidian File - Mono Undercarriage |

|

|

A further demonstration that the monowheel doesn't comply with CS-VLA (in respect of side loads on the main under carriage).

Duncan McF. | Quote: | On 03 December 2022 at 16:44 Pete <peterz(at)zutrasoft.com (peterz(at)zutrasoft.com)> wrote:

Fwiw, my experience:

1- difficulty in getting the gear into to and out of the up-gate (regardless of bungy tension) was due to the flap rod adjustment being too short, causing the flaps to top-out, restricting the gear up travel.

2- general binding of the swing-arm was due to a bent gear/engine frame pivot tube. Bent due to having been side loaded when the gear was in the down position, an angle where that tube is totally unbraced/supported. I suspect many frames in the field are bent. The builder of my bird had actually shimmed the arm bushing to accommodate and reduce the binding (band aid solution). When repairing my frame, i added a truss to the frame at the correct angle to support the tube and prevent any future bending.

3- the bungee is simply to assist the pilot in raising the gear. I tensioned mine such that it pulls the gear up about 60% when doing the gear swing test. I find that with this tension my gear takes minimal effort over its entire swing range in flight.

Cheers,

PeteZ

| Quote: | On Dec 3, 2022, at 9:55 AM, Area-51 <goldsteinindustrial(at)gmail.com (goldsteinindustrial(at)gmail.com)> wrote:

--> Europa-List message posted by: "Area-51" <goldsteinindustrial(at)gmail.com (goldsteinindustrial(at)gmail.com)>

With the 3D aero model now complete its onto a new chapter as mechanical and ancillaries come into the fore; and fruit has arrived straight off the get go.

After reading and hearing about so many issues regarding the mono retract the first thing that has been focused upon is the undercarriage. Having the model available now provides the ability to try things out and get answers almost instantly. So that's exactly what happened as soon as the remaining components of the assembly were drafted and imported into the picture today.

The first goto was undercarriage action; why does it jam closed on some aircraft? Why is it so difficult to retract when throwing that final bit of the lever forward? It was interesting what showed up! An initial earlier solution drafted last year was quickly thrown in the bin but it was this study that revealed where the issue actually now resided.

Having the 3D CAD components assembled allowed a study of the geometry of the retractable assembly, and sure enough it was so very possible to jam the undercarriage in the retracted position; and was remarkably easy to affect; literally just a mm or two beyond the gate stop on the console did it and the wheel was stuck fast in the tunnel void.

It was instantly apparent that the only way this could geometrically be possible is if one of the mechanical arms has moved passed a point to rest within a 90deg quadrant. So that's where the focus went to and thats what was quickly flushed out... the rubber block assembly had crossed over and was resting at 80deg to the swing of its upstream link. And there it was, with the only thing preventing jamming in situ now being the weight of the main wheel overcoming the tension of the bungee spring... Its the very same reason causing that last bit of retract throw on the cockpit lever being difficult; and perhaps the very same reason some owners simply tighten up the bungee spring to get things to park up. (The attached geometry image shows the factory positioning at the blue circles, the magenta line being the 90deg quadrant marker relative to pin LG04's position, the blue line represents the rubber block assembly).

So gee what to do? ?? Well what if things get realigned to their respective 90deg quadrant? worth a go; what's required? Rotate a single pivot point 10deg and revision of LG02A... So that's what got drafted out and presto, problem instantly gone away to the graveyard of great ideas... Amazing!!! Took all of five minutes to solve on the 2D and another 10 to draft up a new 3D functional component and check for clashing and binding.

With pin LG04's position at LG02A now rotated 10deg on the spring blocks arc it is now geometrically impossible to jam the undercarriage; even if the main wheel somehow finds its way up through the tunnel ceiling to the instrument panel facia; which it now can do if the lever is moved beyond its gated travel.

So that's it, MOD-XX... Done!

Fitting of LG02A-XX and reboring of LG02 for LG04's amended position, being 150mm horizontal and 7mm vertical from the datum centre bore of LG03.

The other attached images show the difference between LG02A and LG02A-XX; the position of the bungee pin on LG02-XX has also been raised a few mm for better operational clearance.

So can somebody please explain what the bungee spring actually does??? I cannot find or identify a practical mechanical reason for it at all other than to overcome the existing geometry error; unless this perceived error is intentional?

Thanks for reading everything; well done!

Read this topic online here:

http://forums.matronics.com/viewtopic.php?p=509435#509435

Attachments:

http://forums.matronics.com//files/0c2811c4_5687_479e_8d89_ed360c7f4c9c_437.jpeg

http://forums.matronics.com//files/5c1a69af_790e_4a51_a3bd_8506e15c35f6_343.jpeg

http://forums.matronics.com//files/e8371182_c043_4319_a5aa_c216cd42e8bb_157.jpeg

http://forums.matronics.com//files/f6e8ca6f_6a3a_43da_8d31_fb5ae6e8e277_189.jpeg

http://forums.matronics.com//files/0ef69eca_b797_45ac_828c_7cdc5f70dafb_189.jpeg

|

====================================

====================================

====================================

==================================== |

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

Area-51

Joined: 03 May 2021

Posts: 373

|

Posted: Mon Dec 05, 2022 5:17 am Post subject: Re: The Obsidian File - Mono Undercarriage Posted: Mon Dec 05, 2022 5:17 am Post subject: Re: The Obsidian File - Mono Undercarriage |

|

|

Any aircraft undercarriage or mechanical item for that matter will fail if impacted with enough force; damage to the mono undercarriage from excessive side loaded touchdowns can be mitigated by several ways; one being thought about this afternoon may find its way into the chapter shortly... or be relegated to the graveyard of great ideas.

Keep in mind the undercarriage will not lock up if the bungee tension is less than required to hold the undercarriage above its parked position; the weight of the wheel and gravity is what brings the assembly out of this scenario each time, however the force needed to close out the undercarriage remains constant. The force required to action the undercarriage through the retraction stage is not the same.

The concepts being presented are failsafe engineered to prevent certain situational scenarios occurring.

Somebody mentioned about the operational over center specification; this is an adjustable setting that needs to be maintained regardless.

Dave upstream there asked about how I go about doing this and what software is used... great to hear you are building a model; wishing you well with that! Regarding software; they all provide the same result; buttons are often in different places, same as politicians and beer... I use a few very special ancient tools that few these days know exactly what they each do... A piece of string is the most highly valued, next is a plumb bob, a spirit level but i have been known to use a glass of water during desperate moments, cardboard (cardboard is your best friend), protractor, calipers, a roll of masking tape, good even lighting, a clean floor, a sharp pencil, a blunt pencil, a white board marker, a rheem of plain A4 paper, an adhoc laser pointer on an adjustable tripod, a ruler and tape measure, lots and lots and lots and then some more time, lots of coffee hamburgers, about 30,000 hrs playing CAD, and about 45years of analytical experience.

The model here has taken about 300 hours to measure and a further 1100 to accurately model from the data collected.

| | - The Matronics Europa-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?Europa-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|