|

Matronics Email Lists

Web Forum Interface to the Matronics Email Lists

|

| View previous topic :: View next topic |

| Author |

Message |

valin(at)starflight.aero

Guest

|

Posted: Tue Dec 06, 2016 6:54 pm Post subject: Alternator Field Circuit Fuse Blow Posted: Tue Dec 06, 2016 6:54 pm Post subject: Alternator Field Circuit Fuse Blow |

|

|

Hello Bob,

First, let me say a big thank you for all your help over the years during the design and build of the electrical system of our Lancair Legacy airplane. We’ve been flying now for 14 months, have about 140 hours of flight time, and the airplane received EAA’s Kit Built Grand Champion Award this year. The electrical system has been working very well. It’s based on your Z-12 single battery, dual alternator architecture.

We do have a slight mystery, though, that I would sure appreciate your thoughts on. We’ve had the primary alternator’s (100 A) field circuit fuse blow (fuse not CB) while deploying the landing gear, on two occasions – once two months ago and once this morning.

Here’s some background info. We have a fuse tray that pulls out of the panel holding blade type fuses that light up when they’ve blown -- saved a bunch of real estate on the panel. The landing gear are powered by an electric motor driven hydraulic pump that can pull almost 80 A at times. On the first occasion the field fuse blew I’d eventually attributed it to being because one of our two PC680 batteries (in series for 28 VDC) was heat damaged from sitting down stream of the oil cooler and was not holding a charge well and maybe not compensating for the big current draw from the hydraulic pump motor as well as it should. The battery issue was corrected (replaced) a couple months ago and all has been well until this morning when the field fuse blew again on landing gear extension.

On both occasions the fuse blew on landing gear extension which seems to be the least loaded gear operation since the weight of the gear and their gas spring struts want to deploy the gear anyway – the pump can barely keep up. But, we do have a modification to our landing gear system where the inboard gear doors close after gear go down and the pump typically cycles very quickly several time while it’s closing the inboard doors. For more background, we splurged on expensive hermetically sealed contactors rated for 100 A continuous for switching the hydraulic pump motor -- Tyco Kilovac EV100 relays with built in voltage suppression diodes.

I know you’re the architect of the amazing crow bar over voltage protection featured in our L3RC-28 linear alternator regulator from B & C Specialties. In talking with TJ at B&C today, he said if the regulator sees over 32 VDC for more than 5 milliseconds that the crow bar over voltage will short the field circuit to trip the CB or fuse. We’re both wondering if using a 5A fuse vs. a 5A CB could make a difference…?

Anyway, what do you think about this? It has only happened twice. Could the field current to drive a 100A alternator under a high load exceed the 5A fuse limit? Should we try a 7A fuse? Is this likely from an over-voltage condition and if so what’s causing it? Could it be that the regulator isn’t dropping the field strength fast enough after the landing gear/hydraulic motor stops running and causing an over voltage spike that’s tripping the crow bar over voltage circuit?

Thanks in advance for your help!

Valin Thorn

StarHawk Lancair Legacy -- N321TF

Sedona, Arizona

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

user9253

Joined: 28 Mar 2008

Posts: 1908

Location: Riley TWP Michigan

|

Posted: Wed Dec 07, 2016 7:59 am Post subject: Re: Alternator Field Circuit Fuse Blow Posted: Wed Dec 07, 2016 7:59 am Post subject: Re: Alternator Field Circuit Fuse Blow |

|

|

A circuit breaker is best for this application because breakers take longer to trip than fuses. A breaker will tolerate short spikes of motor starting current that might blow a fuse. But since the plane already has a fuse installed, I would increase the size to 7.5 amps instead of replacing the fuse with a circuit breaker, provided that the crowbar module can handle the extra current in the event of over-voltage. If the 7.5 amp fuse does not blow, then you will know that over-voltage is not the problem, and that the alternator field draws more than 5 amps when the alternator is heavily loaded.

Check the fuse holder to make sure that it tightly grips the fuse. A loose connection will make heat that will eventually blow a fuse.

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

_________________

Joe Gores |

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Dec 07, 2016 9:46 am Post subject: Alternator Field Circuit Fuse Blow Posted: Wed Dec 07, 2016 9:46 am Post subject: Alternator Field Circuit Fuse Blow |

|

|

| Quote: |

On both occasions the fuse blew on landing gear extension which seems to be the least loaded gear operation since the weight of the gear and their gas spring struts want to deploy the gear anyway – the pump can barely keep up. But, we do have a modification to our landing gear system where the inboard gear doors close after gear go down and the pump typically cycles very quickly several time while it’s closing the inboard doors. For more background, we splurged on expensive hermetically sealed contactors rated for 100 A continuous for switching the hydraulic pump motor -- Tyco Kilovac EV100 relays with built in voltage suppression diodes. |

Building a 'fits all' version of a linear regulator

is a real challenge. The regulator is but one component

in a negative feedback control loop wherein EVERY part

of the system has some effect on loop stability.

The major influence on the control equation is the

alternator followed by the battery and then the architecture.

The symptoms you're experiencing are MOST likely a result

of an overshoot transient caused by what amounts to

a 'load dump' under some combination of system loads,

engine rpm, alternator transfer function and battery.

| Quote: | | I know you’re the architect of the amazing crow bar over voltage protection featured in our L3RC-28 linear alternator regulator from B & C Specialties. In talking with TJ at B&C today, he said if the regulator sees over 32 VDC for more than 5 milliseconds that the crow bar over voltage will short the field circuit to trip the CB or fuse. We’re both wondering if using a 5A fuse vs. a 5A CB could make a difference…? |

Actually, the ov trip response is more like 50 milliseconds

but it's not a strictly 'timed' function. I suspect that

everything is operating as-designed but your particular

combination of components and operations is giving you

nuisance trips.

| Quote: |

Anyway, what do you think about this? It has only happened twice. Could the field current to drive a 100A alternator under a high load exceed the 5A fuse limit? Should we try a 7A fuse? Is this likely from an over-voltage condition and if so what’s causing it? Could it be that the regulator isn’t dropping the field strength fast enough after the landing gear/hydraulic motor stops running and causing an over voltage spike that’s tripping the crow bar over voltage circuit?

|

This is not related to field current variations but

simply the regulation characteristics under a load-dump

situation. The 'easy' fix is to modify your regulator

to extend the trip time . . . back when that product

was developed, the sort of 'legacy philosophy' was to

err on the short-side of trip response timing. These

days, my ov protection products are configured a bit

closer to Mil-Std-704 deign goals. In your 28v system,

the voltage would have to remain above 32 volts for

500 milliseconds. That time interval is accurately measured

in software. If the voltage drops below 32 volts any

time during that 500 mS, the time resets and anohter

500 mS trip window is opened.

This is well inside the 32v-for-one-second design rules

for DO-160 compliance.

If you would send me your regulator, I could do the mod

for you.

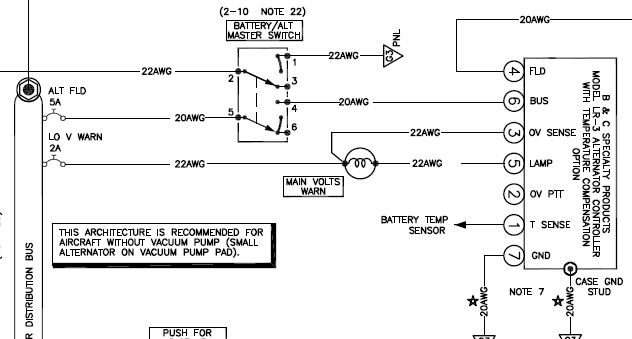

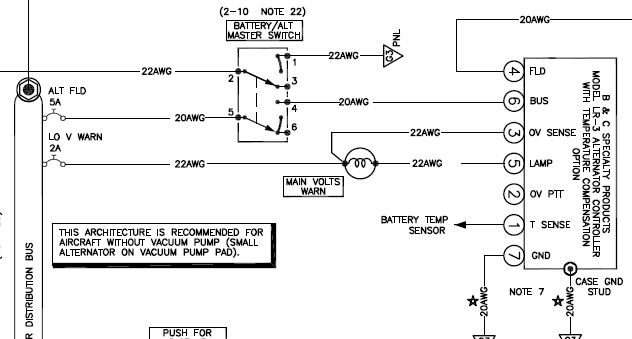

On another matter, using fuses upstream of the crowbar

OVM system is not recommended. This excerpt from Z-12

[img]cid:.0[/img]

. . . shows a circuit breaker feeding the LR regulator's BUS terminal.

The reason for this is based on the precise difficult you're

wrestling with now . . . it's difficult (some cases impossible)

to replace a nuisance tripped fuse on the OV protection system.

[img]cid:.1[/img]

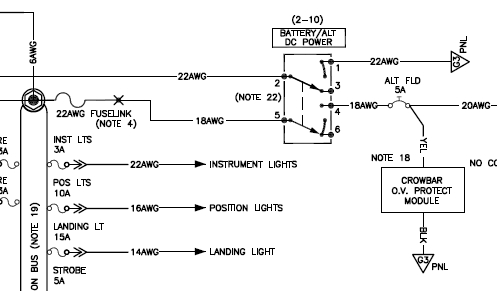

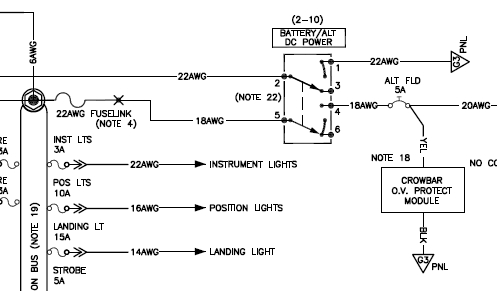

For other architectures where crowbar ov protection is

installed in conjunction with fuse blocks, we show a

FUSIBLE LINK upstream of the alternator field breaker.

Modifying your regulator is probably the solution for

nuisance trips . . . eliminating the ATC fuse in favor

of a 5A breaker is the solution for graceful mitigation

of nuisance trips.

If you choose to go for the modification, coordinate

it with B&C. I'll make sure they know which component

needs to be swapped out for a new value. I could do

the mod but they need to be on board with the

process in case this situation repeat in the

future.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

86.75 KB |

| Viewed: |

7456 Time(s) |

|

| Description: |

|

| Filesize: |

54.48 KB |

| Viewed: |

7456 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Wed Dec 07, 2016 6:46 pm Post subject: Alternator Field Circuit Fuse Blow Posted: Wed Dec 07, 2016 6:46 pm Post subject: Alternator Field Circuit Fuse Blow |

|

|

<snip>

Anyway, it seems that it’s this cycling for inboard gear door closure, when it finally closes the doors, that the fuse is blowing.

Yes, when the pump motor shuts off and the bus voltage overshoots for a few tens of milliseconds.

[/b] Bob, I expect this probably doesn’t change your conclusion that we either need to change to a CB or have the crow bar over voltage circuit adjusted to not trip so quickly with high voltage transients. Thank you so much, by the way, for offering to make that adjustment!

This is not an either/or . . . it’s BOTH.

(1) The fuse is an inconvenient source for crowbar ov protection that is INTENDED to open the source protection . . . better that it’s a crew accessible breaker than a hard or impossible to get at fuse.

(2) Adjusting the r/c time constant of the ov sense circuit will make the system less sensitive to the suspected transients. This is a good thing to do whether or not you change the bus-feeder protection.[/b]

A question before deciding our path forward, since a 5A fuse is more sensitive than a 5A circuit breaker, is Joe’s suggestion to go to a 7.5A fuse in this application an option that might work? Or is that only the thing to do if the problem is that our field circuit current rides close to or higher than 5A under high loads?

Alternator field current is not what’s opening the fuse. When the crowbar ov protection system operates, it throws a dead short on the bus feed line deliberately opening the breaker or fuse. If you made it a 15A fuse it would still pop when the ov protection system gets over=excited.

See http://tinyurl.com/gs6csev for background . . .

[/b]

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

valin(at)starflight.aero

Guest

|

Posted: Wed Dec 07, 2016 8:40 pm Post subject: Alternator Field Circuit Fuse Blow Posted: Wed Dec 07, 2016 8:40 pm Post subject: Alternator Field Circuit Fuse Blow |

|

|

Thanks Bob! I’ll coordinate with B & C. We have two L3RC-28 Linear Regulators (flight and spare on shelf) -- so we’ll send them both in for adjustment, one at a time so the airplane stays in service.

Our fuses are crew accessible in flight. The tray pulls out from the right side of the panel with all the fuse blocks facing the pilot. The Primary Alternator Field fuse is the first one. So, we’ll go ahead and stay with the fuse unless there’s another reason to go CB. I can’t find a good photo to show how it is set up. These two photos should provide an idea. See the face plate with a little pull ring on the right side? That’s the fuse tray face plate, a two foot long fuse tray slides out from there. The second photo shows the fuse tray.

Thanks again,

Valin

[img]cid:image005.jpg(at)01D250D2.5C45D3C0[/img]

[img]cid:image006.png(at)01D250D2.5C45D3C0[/img]

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Robert L. Nuckolls, III

Sent: Wednesday, December 7, 2016 7:45 PM

To: aeroelectric-list(at)matronics.com

Subject: RE: Alternator Field Circuit Fuse Blow

<snip>

Anyway, it seems that it’s this cycling for inboard gear door closure, when it finally closes the doors, that the fuse is blowing.

Yes, when the pump motor shuts off and the bus voltage

overshoots for a few tens of milliseconds.

Bob, I expect this probably doesn’t change your conclusion that we either need to change to a CB or have the crow bar over voltage circuit adjusted to not trip so quickly with high voltage transients. Thank you so much, by the way, for offering to make that adjustment!

This is not an either/or . . . it’s BOTH.

(1) The fuse is an inconvenient source for crowbar ov protection that is INTENDED to open the source protection . . . better that it’s a crew accessible breaker than a hard or impossible to get at fuse.

(2) Adjusting the r/c time constant of the ov sense circuit will make the system less sensitive to the suspected transients. This is a good thing to do whether or not you change the bus-feeder protection.

A question before deciding our path forward, since a 5A fuse is more sensitive than a 5A circuit breaker, is Joe’s suggestion to go to a 7.5A fuse in this application an option that might work? Or is that only the thing to do if the problem is that our field circuit current rides close to or higher than 5A under high loads?

Alternator field current is not what’s opening the fuse.

When the crowbar ov protection system operates, it

throws a dead short on the bus feed line deliberately

opening the breaker or fuse. If you made it a 15A fuse

it would still pop when the ov protection system gets

over=excited.

See http://tinyurl.com/gs6csev for background . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

| Description: |

|

| Filesize: |

150.48 KB |

| Viewed: |

7445 Time(s) |

|

| Description: |

|

| Filesize: |

864.02 KB |

| Viewed: |

7445 Time(s) |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Dec 08, 2016 7:43 am Post subject: Alternator Field Circuit Fuse Blow Posted: Thu Dec 08, 2016 7:43 am Post subject: Alternator Field Circuit Fuse Blow |

|

|

At 10:39 PM 12/7/2016, you wrote:

| Quote: | | Thanks Bob! I’ll coordinate with B & C. We have two L3RC-28 Linear Regulators (flight and spare on shelf) -- so we’ll send them both in for adjustment, one at a time so the airplane stays in service. |

Good lick . . .

| Quote: |

Our fuses are crew accessible in flight. The tray pulls out from the right side of the panel with all the fuse blocks facing the pilot. The Primary Alternator Field fuse is the first one. So, we’ll go ahead and stay with the fuse unless there’s another reason to go CB. I can’t find a good photo to show how it is set up. These two photos should provide an idea. See the face plate with a little pull ring on the right side? That’s the fuse tray face plate, a two foot long fuse tray slides out from there. The second photo shows the fuse tray. |

You guys do good work. There's an aura of

meticulous craftsmanship here. But I'm

a little disappointed that you spent so

much $time$ on the installation of components

with a vanishingly small chance of offering

any in-flight utility.

I would caution that fiddling with fuses,

breakers, or any other failure in flight

is a potential prelude for a bad day in

the cockpit.

When something quits working, it is either

(1) REALLY necessary for comfortable

termination of flight or (2) no big deal.

If the appliance falls in category (1)

you need a backup for it . . . a Plan B.

All appliances in the airplane have MANY

ways to stop working that DO NOT operate

the circuit protection. FBO shops are

populated with airplanes having broke

gizmos, most of which did not pop a breaker

-and- even if they did, resetting the breaker

would not return the appliance to service.

99.999% of all breakers/fuses in airplanes/cars/

boats/garden tractors will set there for

the lifetime of the machine never having

been called upon to do it's singular task:

keep a wire from burning.

Yet, there is a nagging urge to arrange

things with a notion that in-flight diagnosis

and failure mitigation is a good thing to

do.

I've read lots of dark-n-stormy night

stories in the journals . . . I've had

occasion to pick through the bits and pieces

of un-intended contacts with the earth.

All of the accidents I've worked on or studied

with electrical factors were absolutely

preventable by some combination of competent

processes and/or simply having a Plan-B.

That's a beautiful job on the fuse panel

no doubt deserving of honors for craftsmanship.

But my best wish for you is that when something

stops working, that fuse panel is the FURTHEST

thing from your mind while you concentrate on

a comfortable termination of flight.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

valin(at)starflight.aero

Guest

|

Posted: Thu Dec 08, 2016 10:07 am Post subject: Alternator Field Circuit Fuse Blow Posted: Thu Dec 08, 2016 10:07 am Post subject: Alternator Field Circuit Fuse Blow |

|

|

Thanks Bob. The entire interior of our Legacy is our own design and build with the exception of the avionics and joy stick mechanisms. It took many years of weekends… The instrument panel design and layout is ours but the fine work on the instrument panel’s component installation, wiring and fuse tray was performed by Andre Todd at Aerotronics in Montana.

Yes, I agree with your philosophy regarding resetting a tripped CB or fuse in flight. Even our nuisance trips of the field fuse weren’t corrected until on the ground. Even though we built an EAB airplane, we figure there’s a lot of wisdom in the FAR certification regulations and always tried to align with them. That’s why we made the fuses accessible in flight and carry extra fuses with us in flight.

“You guys do good work. There's an aura of meticulous craftsmanship here. But I'm a little disappointed that you spent so much $time$ on the installation of components with a vanishingly small chance of offering any in-flight utility.”

Not sure which low utility components you’re referring to…? Maybe the airplane logo that lights up is one? We certainly did that in part because we think it’s a cool little feature. It may not be clear that it lights up in a color to correspond to the caution and warning status – blue when no issues, yellow for cautions and red for warnings. The Garmin G3X Touch avionics systems will note on the screen when there’s something out of limits – but, it’s just a small little block of words on the PFD that are easy to miss. When the airplane logo changes color, one definitely can’t miss it… We’ve actually been very happy with this feature. Other than that, our design requirements were for an IFR capable aircraft (no FIKI) with appropriate fault tolerance for critical functions.

Thanks again for all you help! I’m about to call TJ at B &C to setup the LR adjustment.

Valin

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Robert L. Nuckolls, III

Sent: Thursday, December 8, 2016 8:42 AM

To: aeroelectric-list(at)matronics.com

Subject: RE: Alternator Field Circuit Fuse Blow

At 10:39 PM 12/7/2016, you wrote:

| Quote: |

Thanks Bob! I’ll coordinate with B & C. We have two L3RC-28 Linear Regulators (flight and spare on shelf) -- so we’ll send them both in for adjustment, one at a time so the airplane stays in service. |

Good lick . . .

| Quote: |

Our fuses are crew accessible in flight. The tray pulls out from the right side of the panel with all the fuse blocks facing the pilot. The Primary Alternator Field fuse is the first one. So, we’ll go ahead and stay with the fuse unless there’s another reason to go CB. I can’t find a good photo to show how it is set up. These two photos should provide an idea. See the face plate with a little pull ring on the right side? That’s the fuse tray face plate, a two foot long fuse tray slides out from there. The second photo shows the fuse tray. |

You guys do good work. There's an aura of

meticulous craftsmanship here. But I'm

a little disappointed that you spent so

much $time$ on the installation of components

with a vanishingly small chance of offering

any in-flight utility.

I would caution that fiddling with fuses,

breakers, or any other failure in flight

is a potential prelude for a bad day in

the cockpit.

When something quits working, it is either

(1) REALLY necessary for comfortable

termination of flight or (2) no big deal.

If the appliance falls in category (1)

you need a backup for it . . . a Plan B.

All appliances in the airplane have MANY

ways to stop working that DO NOT operate

the circuit protection. FBO shops are

populated with airplanes having broke

gizmos, most of which did not pop a breaker

-and- even if they did, resetting the breaker

would not return the appliance to service.

99.999% of all breakers/fuses in airplanes/cars/

boats/garden tractors will set there for

the lifetime of the machine never having

been called upon to do it's singular task:

keep a wire from burning.

Yet, there is a nagging urge to arrange

things with a notion that in-flight diagnosis

and failure mitigation is a good thing to

do.

I've read lots of dark-n-stormy night

stories in the journals . . . I've had

occasion to pick through the bits and pieces

of un-intended contacts with the earth.

All of the accidents I've worked on or studied

with electrical factors were absolutely

preventable by some combination of competent

processes and/or simply having a Plan-B.

That's a beautiful job on the fuse panel

no doubt deserving of honors for craftsmanship.

But my best wish for you is that when something

stops working, that fuse panel is the FURTHEST

thing from your mind while you concentrate on

a comfortable termination of flight.

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Dec 08, 2016 11:12 am Post subject: Alternator Field Circuit Fuse Blow Posted: Thu Dec 08, 2016 11:12 am Post subject: Alternator Field Circuit Fuse Blow |

|

|

| Quote: | | Even though we built an EAB airplane, we figure there’s a lot of wisdom in the FAR certification regulations and always tried to align with them. That’s why we made the fuses accessible in flight and carry extra fuses with us in flight. |

Then you've misread the FARs.

Quoting from Part 23 . . .

---------------------------------

Sec. 23.1357 Circuit protective devices.

(a) Protective devices, such as fuses or circuit breakers, must be

installed in all electrical circuits other than--

(1) Main circuits of starter motors used during starting only; and (2) Circuits in which no hazard is presented by their omission.

(b) A protective device for a circuit essential to flight safety may not be

used to protect any other circuit.

(c) Each resettable circuit protective device ("trip free" device in which

the tripping mechanism cannot be overridden by the operating control) must be

designed so that--

(1) A manual operation is required to restore service after tripping; and (2) If an overload or circuit fault exists, the device will open the circuit regardless of the position of the operating control.

(d) If the ability to reset a circuit breaker or replace a fuse is

essential to safety in flight, that circuit breaker or fuse must be so

located and identified that it can be readily reset or replaced in flight.

(e) For fuses identified as replaceable in flight--

(1) There must be one spare of each rating or 50 percent spare fuses of each rating, whichever is greater; and (2) The spare fuse(s) must be readily accessible to any required pilot.

-------------------------

Okay, name any appliance in your project wherein

failure of that device puts the outcome of your

flight in peril. Assuming you have any such

appliance, then what is your Plan B for dealing

with the failure of that device when it DOESN'T

pop a fuse?

Given that there are dozens of ways in which an

appliance of any criticality can fail that doesn't

pop a breaker/fuse. If the device is critical to

comfortable termination of flight, then you're

advised to have a Plan B for dealing with its

failure.

It follows then that the artfully crafted aircraft

will have NO SINGLE ELECTRICAL APPLIANCE where

failure to function puts the airplane at risk. Hence

making circuit protection for that (or any other)

appliance crew accessible serves no purpose.

| Quote: | “You guys do good work. There's an aura of meticulous craftsmanship here. But I'm a little disappointed that you spent so much $time$ on the installation of components with a vanishingly small chance of offering any in-flight utility.”

Not sure which low utility components you’re referring to…? |

The fuse panel . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

valin(at)starflight.aero

Guest

|

Posted: Thu Dec 08, 2016 12:53 pm Post subject: Alternator Field Circuit Fuse Blow Posted: Thu Dec 08, 2016 12:53 pm Post subject: Alternator Field Circuit Fuse Blow |

|

|

Yes, the key phrase is, “…essential to safety in flight…”. That phrase leaves things open to various interpretations…

In my work we’d try and establish a more objective, measurable safety criteria to compare designs against. We would follow statements like “essential for safety in flight” with criteria of minimum levels of risk as broad as “Loss of Crew” and “Loss of Vehicle” and then break these down into component allocations to subsystems. Then we’d perform probabilistic risk assessments throughout the design cycles to evaluate if those risk targets were achievable with the vehicle’s design. So this would at least create the illusion of some objective measure. But really, it was most useful to help see the elements in the designs that were the biggest influence in risks/safety. Could really never believe the numbers were accurate in an absolute measure.

With that said, yes, all the components/appliances in our aircraft’s electrical system that are critical to some flight phases have redundancy or operational mitigations that help make an good argument that none of them are essential to safety of flight. The failure of each one, though, likely results in some incremental increase in risks. Does it push it past the “essential” criteria? Is a 25% increase in risk make a function essential or is it 50% -- the FAA doesn’t get that specific. And, it depends on what’s going on during the flight when it occurs. If one’s on a precision instrument approach in crummy weather, the probability of a successful approach and landing is higher with all normal systems available and operating. If I felt like I really needed a function/component for what was going on in a flight, I’d probably try and replace a blown fuse once in flight.

So, I agree with you that a strong case can be made for not requiring accessibility in flight for CBs and fuses. I think this design decision was probably influenced by knowing that CBs are usually accessible and in taking the unusual aviation approach of using fuses, I wanted to at least preserve that aspect. It sure would have been easier to mount the fuse blocks on the avionics shelf than to make a deployable tray!

Thanks for your penetrating discussion on this!

Valin

From: owner-aeroelectric-list-server(at)matronics.com [mailto:owner-aeroelectric-list-server(at)matronics.com] On Behalf Of Robert L. Nuckolls, III

Sent: Thursday, December 8, 2016 12:11 PM

To: aeroelectric-list(at)matronics.com

Subject: RE: Alternator Field Circuit Fuse Blow

| Quote: |

Even though we built an EAB airplane, we figure there’s a lot of wisdom in the FAR certification regulations and always tried to align with them. That’s why we made the fuses accessible in flight and carry extra fuses with us in flight. |

Then you've misread the FARs.

Quoting from Part 23 . . .

---------------------------------

Sec. 23.1357 Circuit protective devices.

(a) Protective devices, such as fuses or circuit breakers, must be

installed in all electrical circuits other than--

(1) Main circuits of starter motors used during starting only; and

(2) Circuits in which no hazard is presented by their omission.

(b) A protective device for a circuit essential to flight safety may not be

used to protect any other circuit.

(c) Each resettable circuit protective device ("trip free" device in which

the tripping mechanism cannot be overridden by the operating control) must be

designed so that--

(1) A manual operation is required to restore service after tripping; and

(2) If an overload or circuit fault exists, the device will open the

circuit regardless of the position of the operating control.

(d) If the ability to reset a circuit breaker or replace a fuse is

essential to safety in flight, that circuit breaker or fuse must be so

located and identified that it can be readily reset or replaced in flight.

(e) For fuses identified as replaceable in flight--

(1) There must be one spare of each rating or 50 percent spare fuses of

each rating, whichever is greater; and

(2) The spare fuse(s) must be readily accessible to any required pilot.

-------------------------

Okay, name any appliance in your project wherein

failure of that device puts the outcome of your

flight in peril. Assuming you have any such

appliance, then what is your Plan B for dealing

with the failure of that device when it DOESN'T

pop a fuse?

Given that there are dozens of ways in which an

appliance of any criticality can fail that doesn't

pop a breaker/fuse. If the device is critical to

comfortable termination of flight, then you're

advised to have a Plan B for dealing with its

failure.

It follows then that the artfully crafted aircraft

will have NO SINGLE ELECTRICAL APPLIANCE where

failure to function puts the airplane at risk. Hence

making circuit protection for that (or any other)

appliance crew accessible serves no purpose.

| Quote: |

“You guys do good work. There's an aura of meticulous craftsmanship here. But I'm a little disappointed that you spent so much $time$ on the installation of components with a vanishingly small chance of offering any in-flight utility.”

Not sure which low utility components you’re referring to…? |

The fuse panel . . .

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

nuckolls.bob(at)aeroelect

Guest

|

Posted: Thu Dec 08, 2016 7:10 pm Post subject: Alternator Field Circuit Fuse Blow Posted: Thu Dec 08, 2016 7:10 pm Post subject: Alternator Field Circuit Fuse Blow |

|

|

With that said, yes, all the components/appliances in our aircraft’s electrical system that are critical to some flight phases have redundancy or operational mitigations that help make an good argument that none of them are essential to safety of flight. The failure of each one, though, likely results in some incremental increase in risks.

What is the probability of loss for primary system and it’s Plan-B alternative in any single tank of fuel? FMEA doesn’t deal with increments . . . you either got it or you don’t.[/b] Does it push it past the “essential” criteria? Is a 25% increase in risk make a function essential or is it 50% -- the FAA doesn’t get that specific. And, it depends on what’s going on during the flight when it occurs. If one’s on a precision instrument approach in crummy weather, the probability of a successful approach and landing is higher with all normal systems available and operating. If I felt like I really needed a function/component for what was going on in a flight, I’d probably try and replace a blown fuse once in flight.

FMEA doesn’t care about probabilities and flight conditions are irrelevant. If you have any devic ever critical to comfortable completion of flight, then you’re well advised to have a back-up for it. In 850+ hours of flying rental airplanes, I’ve NEVER perceived an elevated level of risk for not having dug through the maintenance logs of the machines I’ve rented . . . because I was prepared to continue flight to airport of intended destination with a completely dark panel if necessary . . . not searching for the nearest piece of smooth pavement with a 200psi pucker-factor.

The foundation on which all the z-figures are crafted encourages every builder to establish their own minimum equipment list for the most demanding use of the airplane. Then conduct an FMEA while avoiding worrisome and largely irrelevant reliability studies . . . assume that every piece of stuff you bolt to the airplane WILL fail at some point in time . . . then DESIGN IN failure tolerance.[/b]

So, I agree with you that a strong case can be made for not requiring accessibility in flight for CBs and fuses. I think this design decision was probably influenced by knowing that CBs are usually accessible and in taking the unusual aviation approach of using fuses.

But they are NOT all accessible. There are breakers and fuses all over biz jets that crew cannot reach. Heavy iron pilots are generally not allowed to reset ANY breaker (rarely allowed a single reset on some systems) but the foundation for EVERY system powered by ANY breaker stands on a Pl[/b]an-B. It sure would have been easier to mount the fuse blocks on the avionics shelf than to make a deployable tray!

My point exactly and a philosophy I have taught for decades. In dozens of similar discussions dating back to the AVSIG forum on Compuserve I have encouraged builders to craft a FAILURE TOLERANT airplane wherein no single appliance can deprive you of a comfortable termination of flight. The way I used rental aircraft (day/night VFR with occasional punch through for VFR over the top) this compliment of back-ups would let me fly with confidence whether the panel was lit up or not http://tinyurl.com/zqb4f3q

While I was flying off a little airport Dee and I owned about 1989, I crafted some GPS aided approaches to our little chunk of asphalt using dual GPS315 handhelds. I demonstrated an ability to reliably acquire the approach environment under circling minimums . . . with radios totaling $300 and carried in my flight bag. It required preparation and planning with understanding of limits . . . but it wasn’t difficult. Designing a failure tolerant electrical and instrumentation system isn’t difficult either . . . made easier still when panel space used by breakers/fuses is freed up for electro-whizzies that DO something useful.

[/b]

Bob . . .

| | - The Matronics AeroElectric-List Email Forum - | | | Use the List Feature Navigator to browse the many List utilities available such as the Email Subscriptions page, Archive Search & Download, 7-Day Browse, Chat, FAQ, Photoshare, and much more:

http://www.matronics.com/Navigator?AeroElectric-List |

|

|

|

| Back to top |

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Powered by phpBB © 2001, 2005 phpBB Group

|